Introduction

Wire stripping machines are essential tools for anyone working with electrical wiring, whether in construction, recycling, or general maintenance. These machines are designed to remove the insulation from wires, which is crucial for electrical work, recycling, or refurbishing old cables. They make the process faster, more precise, and much safer compared to manual wire stripping methods. In this guide, we’ll cover everything you need to know about wire stripping machines, including their types, features, and how to use them effectively.

What is a Wire Stripping Machine?

A wire stripping machine is a mechanical tool that removes the insulation from electrical cables. The goal is to expose the wire’s conductive core so that it can be used for wiring or sold as scrap metal, especially in the case of copper wires. The machine works by feeding the wire through a set of cutting blades that peel away the insulation without damaging the core material.

Wire stripping machines come in various forms, from manual models for smaller jobs to electric and pneumatic models designed for high-volume industrial tasks. The primary advantage of using these machines is the speed and precision they offer.

Types of Wire Stripping Machines

Wire stripping machines can be categorized based on their power source and intended use. Here’s an overview of the different types:

● Manual Wire Strippers

These are basic, hand-powered tools ideal for small-scale jobs. They are compact, portable, and require a bit of manual labor, making them perfect for DIYers or occasional users.

● Electric Wire Stripping Machines

These machines are powered by electricity and are more efficient for larger tasks. They are faster, and more precise, and can handle a range of wire gauges. Electric wire strippers are commonly used in workshops and small businesses.

● Pneumatic Wire Strippers

These are high-performance machines powered by compressed air, often found in industrial settings. They offer greater precision and efficiency, making them ideal for high-volume stripping applications.

● Laser Wire Strippers

The cutting-edge option in wire stripping technology, laser machines use focused light beams to remove insulation without touching the wire, offering a high level of precision and minimal wear on the wire.

Key Features to Consider When Choosing a Wire Stripping Machine

When choosing a wire stripping machine, it’s essential to consider several factors to ensure you’re selecting the right one for your needs. Here are the key features to keep in mind:

● Wire Gauge Compatibility

Ensure the machine can handle the gauge of wire you’ll be working with. Some machines can strip wires from as thin as 24 AWG (American Wire Gauge) to as thick as 1/0 or even larger.

● Cutting Mechanism

Machines can use rotary blades, razor cutters, or other mechanisms. The cutting method impacts the speed and precision of the stripping process.

● Speed and Efficiency

Faster machines may be necessary for high-volume or industrial applications. Consider how much work you need to do and choose a machine accordingly.

● Portability and Size

If you plan on moving your machine around, look for a lightweight and compact model. If it’s for a fixed workstation, a larger, more powerful model might be preferable.

● Safety Features

Look for features such as emergency stop buttons, safety shields, and automatic shut-offs to ensure the machine is safe to use in various environments.

Benefits of Using a Wire Stripping Machine

There are many reasons why you should consider using a wire stripping machine:

● Saves Time and Labor

Stripping wires manually can be slow and tiring. A wire stripping machine accelerates the process, freeing up time for other tasks.

● Increases Recycling Efficiency

For those involved in recycling, wire stripping machines allow you to quickly remove insulation from copper wires, increasing the scrap value of your materials.

● Ensures Precision and Reduces Waste

These machines provide a more accurate and consistent strip than manual methods, minimizing the risk of damaging the wire’s core.

● Improves Safety

The risk of injury is reduced when using a wire stripping machine, as opposed to using tools like knives or scissors for manual stripping.

How to Use a Wire Stripping Machine (Step-by-Step Guide)

Step 1: Safety First

Before using any wire stripping machine, make sure you’re wearing protective gear such as gloves and safety glasses.

Step 2: Prepare the Machine

Set the machine up according to the manufacturer’s instructions. Adjust the settings based on the gauge of the wire you are using.

Step 3: Feed the Wire

Place the wire into the machine’s input slot and secure it according to the type of machine you are using.

Step 4: Start the Stripping Process

Activate the machine to start stripping the insulation from the wire. The machine should automatically pull the wire through the blades and strip the insulation without damaging the core.

Step 5: Inspect the Results

After stripping, check the wire to ensure the insulation has been completely removed without damaging the conductor. Adjust the machine settings if necessary.

Step 6: Maintenance

To keep your wire stripping machine in good working condition, regularly clean the blades, check for wear, and replace parts as needed.

Common Mistakes & Troubleshooting

Even with a wire stripping machine, you might encounter some issues. Here are some common mistakes and how to troubleshoot them:

● Incorrect Wire Gauge Settings

If the machine is set to the wrong wire gauge, it may not strip the wire properly or could damage the core. Double-check the settings before use.

● Dull Blades

Over time, the blades can become dull. Regularly inspect the blades and replace them when they no longer cut efficiently.

● Tough Insulation

Some wire insulation is tougher than others. In such cases, adjust the blade pressure or use a higher-powered machine to deal with tougher materials.

● Damage to Wire Core

This can occur if the machine is not properly adjusted or if too much pressure is applied. Make sure to set the machine for the correct wire thickness and insulation type.

Best Wire Stripping Machines in the Market

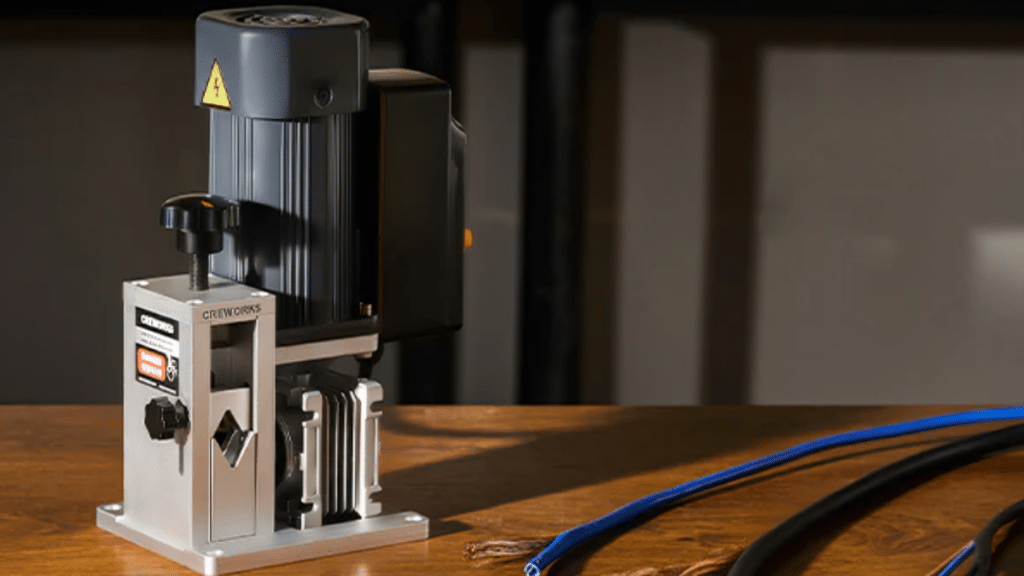

If you’re in the market for a wire stripping machine, Creworks offers two exceptional models that cater to a wide range of needs. Their manual wire stripping machines are ideal for DIYers and small workshops, offering easy-to-use, lightweight designs that handle various wire gauges with precision for smaller tasks. On the other hand, their automatic wire stripping machines are ideal for high-volume projects, efficiently stripping multiple wires at once and accommodating a range of wire gauges, making them ideal for larger-scale operations.

Conclusion

Wire stripping machines are a must-have tool for anyone who works with wiring regularly. They provide an efficient, safe, and cost-effective way to strip insulation from wires, whether you’re a professional in an industrial setting or a DIY enthusiast. By choosing the right machine for your needs, you can save time, reduce waste, and increase productivity. Investing in a high-quality wire stripping machine, such as those offered by Creworks, will ensure that you get the job done right with minimal effort and maximum efficiency.