The advances in artificial intelligence (AI) have opened up a world of possibilities for 3D printing applications. AI has enabled the creation of complex and intricate objects with high precision, and helps us save time, money and resources while achieving great results with abs plastic materials in 3D printing projects. As 3D printing materials such as abs plastics become more advanced and more accessible to the average user, AI will enable users to bring their innovative ideas to life with greater accuracy and in shorter amounts of time. The possibilities of what can be created with this powerful combination of 3D printing and AI technologies are vast and exciting, making it a crucial tool for businesses wanting to stay competitive in our rapidly changing digital world.

Improve the quality and accuracy of 3D prints

AI helps to improve the quality and accuracy of 3D prints by providing a more precise control over the printing process. With AI, it is possible for printers to accurately predict, fine-tune, and adjust parameters such as heat, speed, and layer thickness. This precision enables 3D prints with greater detail and accuracy than previously achievable. Additionally, AI can help identify errors in real time during the printing process and correct any misalignments or irregularities before they become major issues. This helps ensure that each finished product meets high standards of quality and durability. Finally, AI can be used to automate certain aspects of the printing process such as pre-processing steps like slicing or post-processing operations like sanding or polishing, further improving the quality and accuracy of 3D prints. Overall, AI provides a powerful tool for creating high-quality, accurate 3D prints.

Speed up the process of creating 3D printed objects

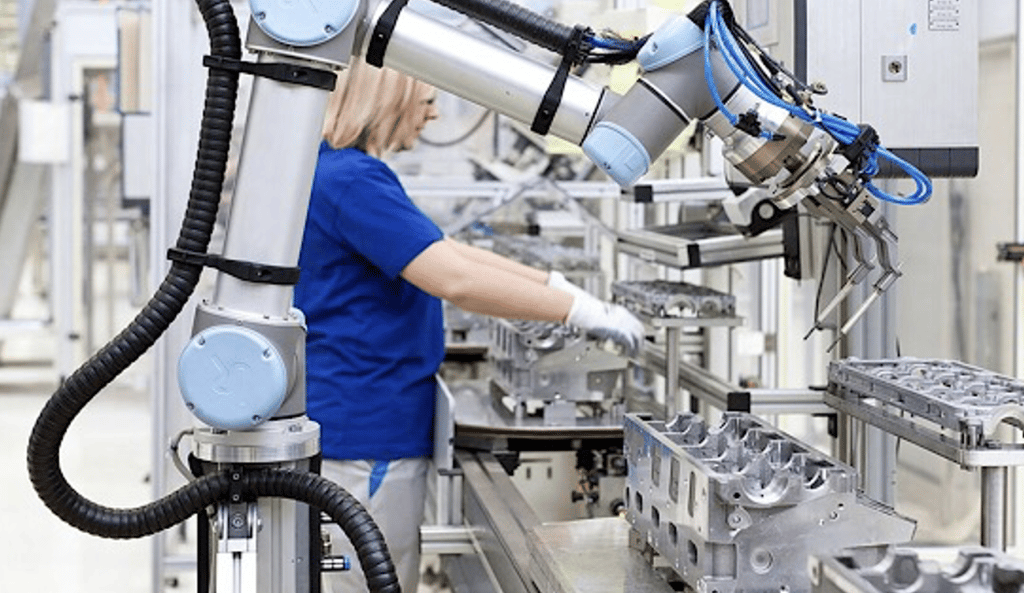

AI technology can help to speed up the process of creating 3D printed objects, provide greater accuracy in designs and offer a much wider range of creative options than traditional methods. By using AI-assisted 3D printing, designers have access to more powerful tools that can reduce time and cost when creating prototypes or specialized parts. One advantage of using AI with 3D printing is improved automation. Designers can set parameters for the object they wish to print and the machine will automatically calculate optimal settings for its production.

Reduce the complexity of design

AI can also help to reduce the complexity of design by automatically generating a pattern of curved surfaces, based on user input parameters. This has enabled 3D printing designers to create more complex and intricate shapes than ever before, with greater accuracy and faster turnaround times. AI-assisted 3D printing is also great for creating personalized designs or parts tailored to specific specifications. By using intelligent algorithms, designers are able to quickly produce objects that have been customized for various purposes such as medical implants, consumer products, automotive components or aerospace parts.

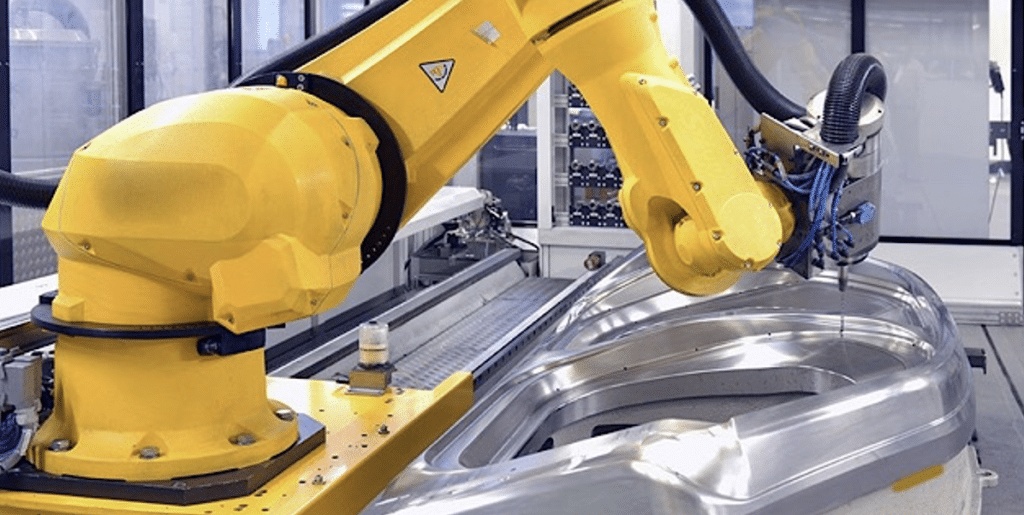

Finally, AI-assisted 3D printing can help increase productivity and output levels by reducing the time needed for labor intensive tasks such as quality control or post-processing activities. These benefits make it easier for businesses to produce more products or services in less time, with higher quality and greater efficiency.

The benefits of using AI with 3D printing are clear, making it an invaluable tool for any business looking to reduce costs and improve production levels. With the right implementation and understanding, this technology can help businesses stay competitive in the market and create high-quality designs that meet their customer’s needs.

In conclusion, AI-assisted 3D printing has revolutionized the design process in many industries. From increased automation to improved accuracy, this technology offers a wide range of benefits that make it easier for businesses to produce products quickly and cost effectively. With this powerful tool, designers are able to create more complex designs with greater precision and efficiency than ever before. This makes it an invaluable asset for any company looking to stay competitive in the market and produce high-quality parts or objects in a timely manner.

AI Technology is Vital to Modern 3D Printing for the Manufacturing Industry

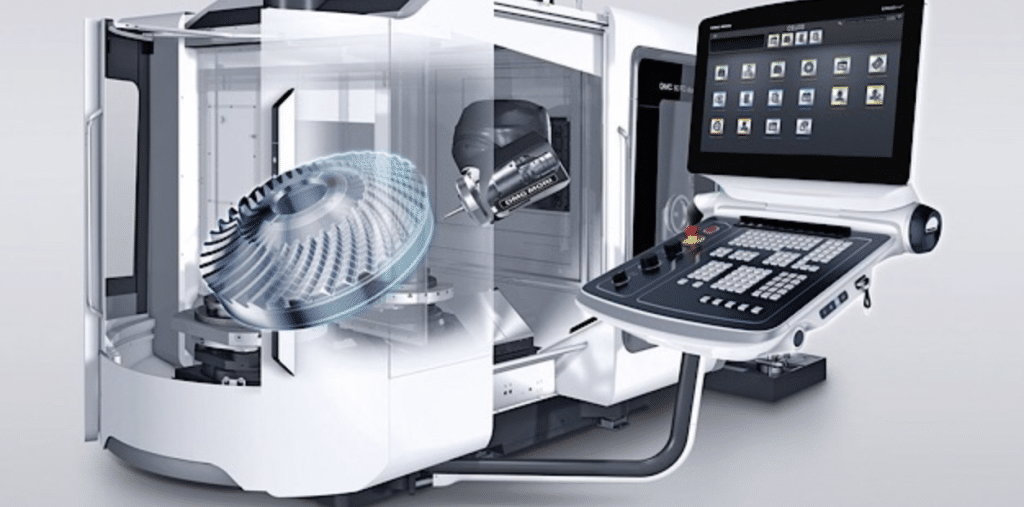

The potential of AI for modern 3D printing lies in its ability to automate the process of designing parts and components from the beginning to end. This includes the creation of a computer model from scratch, assessing both mechanical and aesthetic criteria before creating a part or component, simulating how it will behave in different environments, optimizing the physical properties of materials used during production, diagnosing any defects or issues with parts, and more.

The applications of AI-powered 3D printing are vast and range from automotive production to creating medical implants. In the automotive industry, AI is able to rapidly prototype parts that can be tested in different environments before being approved for mass production. In the medical field, 3D printed implants can be tailored according to a patient’s specific anatomy, making surgery more precise and successful while reducing recovery time.

AI technology is revolutionizing the manufacturing industry by increasing speed and accuracy when it comes to producing complex parts and components using 3D printing technologies. With its predictive analytics capabilities, AI offers manufacturers a level of control and accuracy that would otherwise not be attainable.