In the world of bulk material handling, staying ahead of the curve is crucial for any business. From the food and beverage sector to pharmaceuticals and industrial materials, innovative solutions are shaping the future. Among these advancements, enclosed tubular technology stands out as a game-changer.

What Is Enclosed Tubular Technology?

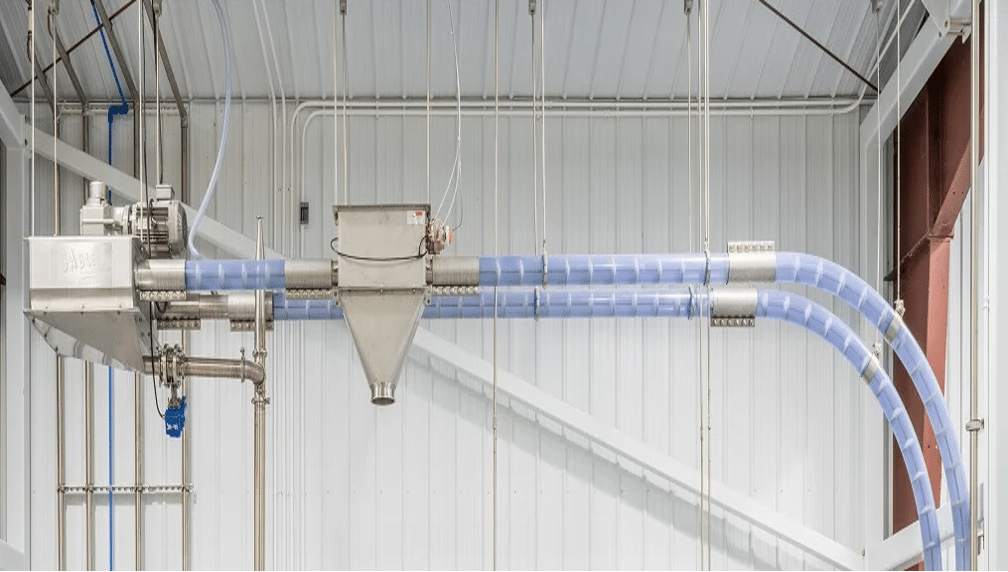

Imagine a sophisticated network of tubes specifically engineered to transport numerous delicate materials—be it grains, freshly ground coffee, pet food, or sensitive pharmaceutical compounds—from their starting point to their final destination.

In the materials handling sector, this system is known as “Enclosed Tubular Technology.” Its purpose is simple but crucial: to move large quantities of material efficiently and safely while preserving the integrity of the products.

Why It Matters

Traditional methods of moving bulk materials have their limitations. These systems often expose the materials to open air, moisture, and contaminants or subject them to mechanical stress that can degrade quality.

This is a particular concern with friable materials, which are fragile and easily broken or degraded. Examples include foods like breakfast cereals, certain pharmaceutical components, and even industrial products like plastic pellets.

Features and Innovations

The technology behind enclosed tubular conveyors has come a long way, adapting to the growing and varied needs of different industries. With over twenty patented innovations in its toolkit, this technology isn’t just keeping pace with the times; it’s setting new standards.

- Traditional conveyors usually operate at a constant speed, but advances in enclosed tubular technology have introduced special discs that adjust to variable speeds. This feature ensures even more gentle handling of delicate materials,

- Older systems are limited by gravitational flow, while modern enclosed tubular technology operates at various angles. Uphill, downhill, or around corners, the system is up for the challenge,

- Built-in features ensure that the transported material retains quality. Whether moving grains, powders, or pharmaceuticals, the closed system helps maintain the integrity of the product by minimizing exposure to environmental contaminants,

- Advanced design and materials have led to systems that consume less energy compared to traditional methods, contributing to cost savings and a smaller carbon footprint,

- Many modern systems now come with real-time monitoring features, enabling quick diagnostics and timely maintenance. This is like having a built-in health check for your material-handling process.

Sustainability: More Than Just a Trend

Sustainability is far more than just a catchphrase or a box to tick. With the urgency surrounding climate change and the depletion of natural resources, making conscious choices about the technology we use has real-world implications.

The precise and gentle handling of materials minimizes waste due to breakage or spillage, ensuring that resources are fully utilized. High-quality construction and materials mean that these systems have a longer lifespan, reducing the frequency of replacements and conserving resources in the long term.

Why Companies Trust This Technology

The reputation of enclosed tubular technology isn’t built on marketing hype; it’s been earned through consistent performance, reliability, and a proven track record of handling materials gently and efficiently. This is why some of the biggest names in various sectors, particularly in the food processing industry, rely on this technology.

- Systems are built to last and to maintain consistent performance over time. This means less downtime and more productivity for businesses,

- Gentle handling ensures the quality and integrity of delicate and friable materials, meeting the high standards set by industry leaders,

- Enhanced features like variable speed control and multi-angle capabilities allow for streamlined operations, improving overall productivity,

- The closed system contributes to a safer and more hygienic work environment, a factor especially crucial in sectors like food processing and pharmaceuticals.

Make Cablevey Conveyors Your Chosen Technology

If you’re in an industry dealing with bulk material handling—whether it’s food, pharmaceuticals, or industrial materials—consider adopting enclosed tubular technology.

Companies like Cablevey Conveyors offer advanced systems that take your material handling to the next level. The future of bulk material handling is enclosed, efficient, and sustainable. It’s not just a conveyor; it’s a complete system designed to make your operations better in every possible way.