In electronics, PCB design and manufacturing govern the functionality and reliability of the end product. The convoluted processes, ranging from material selection to layer stack-up alignment and copper etching to solder mask application, all impact the printed circuit board’s electrical performance, thermal properties, and mechanical stability.

Further, the worth of unified PCB design-to-manufacturing integration cannot be overstated. Such integration ensures design fidelity, eradicates production bottlenecks, and cuts costly manufacturing defects. Moreover, the extensive need for the products has promoted the emergence of quick-turn PCB services. Thus, a careful and synchronized approach throughout the entire PCB design and manufacturing workflow is vital to the success or failure of electronic devices in the market.

The Basics of PCB (Printed Circuit Board)

1. Definition and Purpose of PCBs

Printed Circuit Boards (PCBs) are foundational ingredients in most electronic devices while serving as both conduits and platforms for components. They facilitate electrical connections between different components. Remember, PCB design and manufacturing assist in ensuring resourceful and unfailing electronic circuit functionality.

2. Different Types of PCBs

. Rigid Board

It is typically made from fibreglass (like FR-4). Known for its durability and stiffness, these are the most common in PCB design and manufacturing.

. Flex Board

This type of PCB is crafted from flexible polyimide or similar materials. It allows for bending and flexing during application and offers design versatility.

. Metal Baseboard

It features a metal substrate (aluminium or copper). Also, it provides better thermal performance for effective heat dissipation in high-temperature applications.

The PCB Manufacturing Process

Next, let’s discuss the manufacturing process of printed circuit boards.

1. PCB Development

In the initial phase of PCB development, engineers use dedicated software to create a detailed blueprint for the desired circuit. The complexity varies, from single-layer boards to multi-layer designs where signals and power traverse between layers via plated-through holes (PTH). A noteworthy step in this phase is the “Design for Manufacturability” (DFM) check. It ensures that the PCB design and manufacturing process align. For example, ensuring trace widths can handle the desired current or verifying adequate spacing to avert unintentional short circuits.

2. PCB Fabrication Process

After finalizing the design, the PCB fabrication process commences. Here, the board undergoes several complex steps to apply a photo-sensitive film to the laminate material. The unexposed areas are chemically removed once exposed to light through the circuit pattern for desired copper traces. Multi-layer boards undergo lamination processes, where individual layers are bonded using heat and pressure. Likewise, chemical plating is ordinarily utilized to strengthen the plated-through holes PTH. As an illustration, consider the creation of a four-layer board. Inner layers may carry power, while outer layers handle signal routing. Each layer is carefully aligned and laminated together.

3. PCB Assembly Process

The assembly process is crucial in PCB design and manufacturing, which involves placing components onto the fabricated PCB. Surface Mount Technology (SMT) is dominant, where components are directly soldered onto the board’s surface. In contrast, the traditional Through-Hole Technology (THT) entails inserting component leads through holes and soldering them on the opposite side. The selection between SMT and THT depends on the specific circuits and production requirements. SMT is favored for its space-saving benefits and suitability for automated assembly, while THT is utilized when robust mechanical connections or higher power handling capabilities are necessary.

4. Quality Control and Testing During Manufacturing

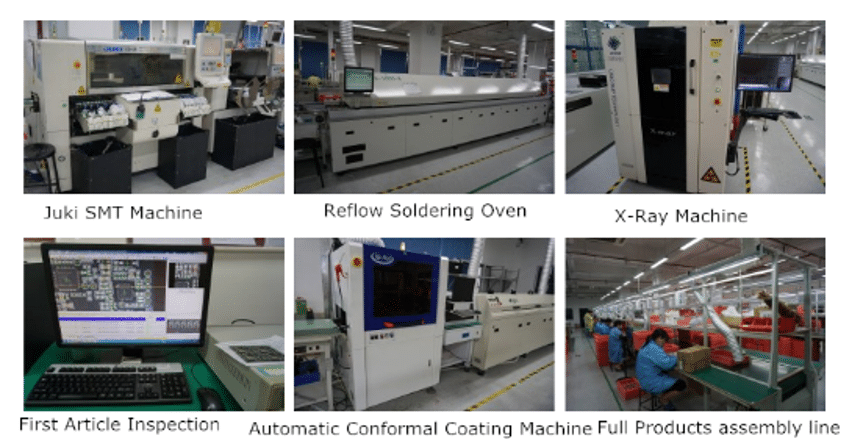

Confirming the integrity of the PCB design and manufacturing outcome is vital. Thus, quality control and testing is required. To achieve this, various methods and machines are employed.

. Automatic Optical Inspection (AOI) machines play a crucial role in scrutinizing the PCB for any discrepancies, such as missing components or solder bridges. These machines are adept at identifying any irregularities in the board.

. In addition to AOI machines, solder paste inspection (SPI) machines are utilized. SPI machines are capable of measuring the height, volume, and area of solder paste deposits. They also calculate stencil offsets and identify defects in the PCBs.

. Furthermore, a first article inspection (FAI) is conducted on the initial assembled board before mass production begins. The purpose of this inspection is to ensure that there are no assembly errors that could affect the quality of the final product.

How to Choose A PCB Manufacturing Company?

When selecting a PCB manufacturing partner, prioritize valuing their PCB design and manufacturing processes expertise:

. Assess their capability to produce complex layouts and multi-layer boards.

. Examine their quality control measures for the absence of soldering defects or component misalignments. Inquire about their adherence to quality standards to gauge the quality of their finished products.

. Plus, scrutinize their certifications, such as UL and ISO9001, which indicate an obligation to quality and reliability.

. Weigh the cost and lead time to offer a balance that supports your project’s budget and timelines while considering potential hidden charges.

YLC King: A Leading Printed Circuit Board Manufacturer

Among the choices, YLC King stands out as a reliable PCB board manufacturer. Originating from Shenzhen, they’ve established an all-encompassing, one-stop platform that transitions from product design and development to advanced PCB manufacturing.

1. Product Design and Development

YLC King is committed to helping customers turn their ideas into reality, providing expert product design and development services.

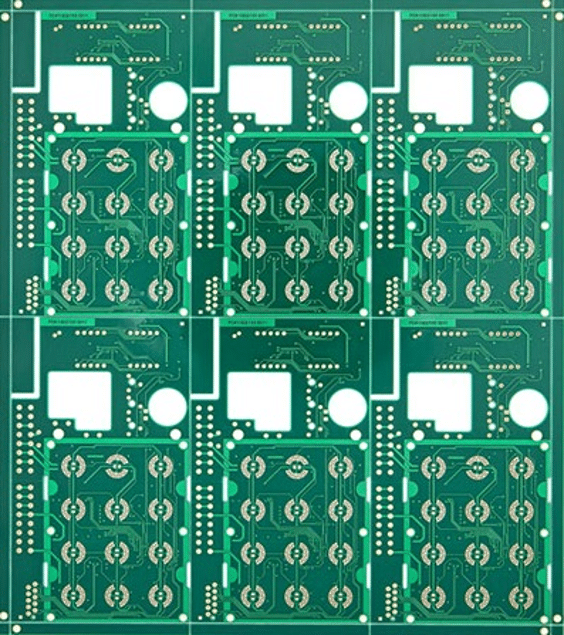

2. PCB Manufacturing

With state-of-the-art facilities and cutting-edge technology, YLC King is capable of producing high-quality PCBs tailored to diverse specifications.

3. Surface Mount Technology (SMT) Assembly and Testing

YLC King goes the extra mile to ensure precision and reliability by offering SMT assembly and rigorous testing, guaranteeing the utmost product quality.

4. ODM and OEM Services

YLC King provides a seamless fusion of ODM and OEM services, exemplifying their commitment to meeting various customer needs and industry demands.

Conclusion

With PCB’s significant influence in promising the smooth function of equipment, decisions could be made after careful consideration. With the capability to provide a one-stop solution for international customers, YLC King won its reputation in PCB design and manufacturing for producing premium products at competitive prices. Moreover, ODM and OEM services that are available will help you to achieve a satisfactory deal.