Wondering if a Dibond sign fits your needs? This resilient aluminum composite is not just strong—it adapts to your creative vision and stands up to outdoor elements with ease. In the following sections, we’ll cover what makes Dibond a wise choice, from its material advantages to the range of design possibilities it offers, paving the way for you to decide if it aligns with your sign requirements.

Key Takeaways

- Dibond signs exhibit exceptional durability, weather and corrosion resistance, and versatility in design and application, suitable for long-term outdoor and high-end indoor displays.

- Customizable options for Dibond signs are extensive, ranging from size, shape, and finish to printing and mounting options, facilitating tailored solutions for businesses, artists, and interior designers.

- While Dibond signs may carry a higher initial cost compared to other signage materials, their longevity, low maintenance, and full recyclability provide long-term cost savings and environmental benefits.

Understanding Dibond Signs: Material and Characteristics

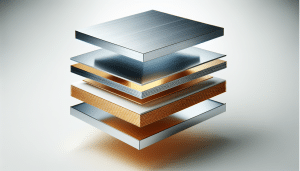

At the heart of Dibond signs, also known as aluminum sandwich boards, is an ingenious sandwich-like structure: two aluminum layers enveloping a polyethylene core. This fusion results in an exceptionally durable and rigid signage material with a Class A fire rating, making it ideal for long-term use in various settings.

But these signs aren’t just about strength; they are a canvas for creativity, offering a smooth, professional appearance that can mirror a reflective effect or take on different finishes, including white, brushed silver, and bronze. As a versatile sign material, Dibond signs are perfect for eco-conscious businesses, as they are fully recyclable.

Aluminum Composite Material

Dibond signs owe their robustness to the aluminum composite material they’re crafted from, a unique combination of two aluminum sheets fused to a core layer. This core layer is made of polyethylene, a type of plastic, creating a sandwich that offers incredible rigidity and durability. The result? An aluminum composite panel that’s ideal for various business sign applications.

And when it comes to longevity, Dibond doesn’t disappoint. Its composition ensures resistance to rust and bending, so your sign can stand tall and proud, maintaining its aesthetic appeal for years to come.

Weather and Corrosion Resistance

When designing outdoor signage, weather resistance is a top priority. Dibond signs answer this need exquisitely, thanks to the corrosion resistant aluminum sheets used in their creation, which lend them excellent weather-resistant qualities. Rain, snow, or heat, these signs remain unfazed, making them reliable performers in all outdoor conditions. Furthermore, Dibond signs are highly resistant to corrosion, retaining their shape and flatness without rusting or bending. This resilience is crucial for outdoor business signage and applications where a metallic finish is desired without the weight or risks associated with metal.

So, not only do Dibond signs weather the elements with grace, but their longevity and quality retention in harsh conditions also make them a cost-effective choice. The durable, non-corrosive material results in less frequent sign replacement, translating to long-term economic savings.

Customizing Your Dibond Sign: Design and Options

One of the notable strengths of Dibond signs is their high customizability, which allows them to be tailored to suit diverse architectural and design needs. You can opt for standard forms or custom contours, all precision-cut using CNC routers. Size-wise, Dibond signs offer an impressive range from 4×4 inches to 48×96 inches, giving you the flexibility to choose the perfect fit for your requirements.

And it doesn’t stop there. You can enhance your Dibond sign’s visibility with a gloss UV finish and opt for printing on either one or both sides. The white coated surface on both sides ensures vivid and high-quality print results. Whether you leverage free design templates, an online design tool, or assistance from an in-house graphics team, designing a custom Dibond sign is a breeze.

Shape and Size Flexibility

Dibond signs offer an impressive range of options:

- Sizes range from as small as 6” x 6” to large seamless sheets of 5’ x 10’, or even two sheets mounted together for larger dimensions

- Shape options include pointed corners or rounded corners for a polished finish

- Custom cutting options like contour cuts and outline cuts allow for tailored designs

- ‘Halo’ and ‘Special’ cuts are available for an extra touch of originality

Dibond signs’ advanced customization extends to intricate designs and shapes, such as company logos or custom signs with cut-out designs, as well as perfect round shapes and oval finishes. With dibond sign printing, you can achieve these unique designs effortlessly by ordering dibond signs online.

Finishing Touches

The right finishing touches can make a world of difference in the look and feel of your signage. UV curing printers apply inks to Dibond signs that are dried using UV rays, helping graphics remain vivid and sun-resistant. Additionally, applying a gloss or matte UV laminate enhances a Dibond sign’s appearance, providing sun protection and adding to its longevity. This UV protective laminate can prolong their outdoor life expectancy to between 5 and 7 years.

If you’re aiming for a modern or industrial aesthetic, a brushed aluminum finish is a great choice. And for added visual appeal, consider a shiny, reflective finish to catch the eye. Lastly, if you require versatile and multi-directional display options, double-sided printing is available.

Installation and Display Choices for Dibond Signs

Dibond signs’ versatility extends to their installation as well. You can mount them using various hardware such as standard screws, bolts, or standoffs for an elegant presentation. Installation methods range from using heavy-duty double-sided tape or silicone for direct adhesion to rail mounting systems for larger signs, ensuring accurate hole alignment for secure standoffs, and reinforcing edges with corners grommets.

But don’t let these options intimidate you. The lightweight property of Dibond signs simplifies their handling and installation, making them effectively versatile for diverse business environments and locations.

Mounting Options

Dibond signs offer a wide array of mounting options to suit your needs. Some options include:

- Standoffs: aluminum mounting hardware that separate the sign from the wall for a contemporary look

- Edge-grip standoffs: provide a drill-free option

- Sawtooth hangers: for smaller and lightweight signs

- Foam-board pieces with double-sided tape: another option for smaller and lightweight signs

Larger signs might need more robust methods like drilling holes for hanging. Dibond signs can be flexibly mounted with:

- substrate grommets in various positions

- set on A-frame stands for portability and easy display change

- achieving a floating effect using split batten mounting, subframe mounting, or by minimizing mount visibility, directing focus to the Dibond sign itself.

Display Considerations

When it comes to displaying your Dibond sign, several factors play a crucial role in maximizing its visibility and impact. First, the display location should be selected based on line of sight and the distance from which it will be viewed to ensure maximum visibility and readability. Proper lighting is also essential to enhance your Dibond sign’s visibility, especially in areas with low light or for displays during nighttime.

The orientation of your Dibond sign, whether landscape or portrait, coupled with a suitable size, can have a significant impact on its effectiveness. For instance, larger signs are ideal for outdoor high-traffic areas. If you need temporary displays or where repositioning is needed, lightweight Dibond signs can be mounted using hook and loop fasteners, offering easy removal and relocation.

Popular Applications of Dibond Signs

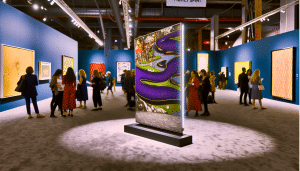

Dibond signs have found a wide array of applications, thanks to their sheer adaptability in various signage contexts. They are incorporated into modern architectural designs both for their aesthetic properties and functional roles such as insulation and wall linings. Artists and exhibitors frequently turn to Dibond signs for fine art applications, performance sets, and both indoor and outdoor exhibition kiosks, thanks to the material’s durability and premium visual quality.

Signage companies leverage Dibond signs for:

- Creating customized channel letters

- Creating signage

- Creating type II electrical enclosures

- Meeting the needs of various businesses like restaurants and beauty salons.

Business and Corporate Signage

Custom Dibond signs can be exclusively designed to meet specific business requirements, allowing adaptation in terms of:

- Design

- Size

- Color

- Finish

- Installation options

This ensures that the brand is represented accurately and effectively. The brushed aluminum finish available with Dibond signage offers a sleek and sophisticated aesthetic, aligning with the branding needs of contemporary businesses.

In addition to their premium appearance, Dibond signs have the adaptability to be effectively utilized in multiple environments, making them suitable for both indoor and outdoor applications in the corporate world. They also excel in creating wayfinding systems within experiential design projects, aiding in both navigation and branding purposes.

Artistic and Decorative Displays

The world of art and interior design has also embraced the versatility of Dibond signs. They are increasingly featured in art exhibitions and galleries, utilizing their strong metal layers and plastic core for displaying high-quality visual artworks. Interior decorators leverage the attractive features of Dibond prints for stylish interior design, taking advantage of their polished look and brushed aluminum finishes.

Customization of Dibond signs has been enhanced by CNC cutting technology, allowing artists to create bespoke designs in vibrant patterns or unique shapes. Additionally, shadow box mounting offers a contemporary framing alternative for Dibond artworks, attaching a hanger diagonally across the frame’s top corners for a discrete and elegant display.

Caring for Your Dibond Sign: Maintenance and Lifespan

Like any investment, Dibond signs require proper care to ensure their longevity. Typically, Dibond signs have a lifespan of 5 to 7 years. In less extreme weather conditions, Dibond signs can last for up to 10 years.

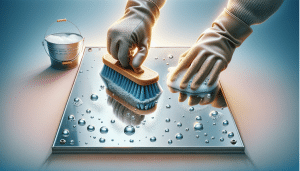

To clean Dibond signs, mild soap and water should be used. UV-coated permanent LED inks are used for Dibond signs, which are designed to remain vibrant and resist fading over time when properly cared for and cleaned.

Cleaning and Maintenance

Proper cleaning and maintenance can significantly extend the lifespan of Dibond signs. Here are the steps to follow:

- Use soft cloths and mild soap to clean the surface.

- Be cautious of items like buttons and belt buckles that may scratch the surface.

- Wet the surface.

- Clean with soapy water.

- Rinse.

- Dry with a soft cloth.

For coated Dibond surfaces, use mild shampoos and terry cloth for cleaning, and microfiber cloths for drying. Outdoor signs contaminated with algae or soot should be cleaned with a soft brush and mild detergents. When transporting Dibond signs, protect them with non-abrasive foam sheets, and avoid using a high-pressure sprayer on coated surfaces to prevent damage.

Expected Lifespan

Dibond signs can have a significant lifespan, lasting up to five years outside with minimal fading, or over ten years indoors. The use of UV curing printers ensures the colors on Dibond signs are sun-resistant, which aids in maintaining their original vividness over time.

Applying UV laminates adds an additional layer of protection against damaging UV rays, further extending the lifespan of Dibond signs, especially when exposed to sunlight.

Comparing Dibond Signs to Other Signage Materials

In the world of signage, Dibond signs stand out from other sign materials by their balance of durability, lightweight properties, and premium aesthetics. While acrylic signs are sturdy and UV resistant, they lack the lightness of Dibond and can be difficult to repair if damaged. Aluminum signs, although lightweight and durable like Dibond, are susceptible to denting and may negatively affect visibility by reflecting light. PVC signs offer durability and resistance to weather at a lower weight compared to acrylic, but unlike Dibond, they can chip easily.

Coroplast, as an economical temporary signage material, is prone to warping and lacks the permanent, high-end appearance of Dibond signs. Given this analysis, Dibond signs are best suited for long-term outdoor and high-end indoor displays where durability, lightness, and aesthetic value are key considerations.

Pros and Cons

Dibond signs are more durable than Coroplast signs and can offer a longer lifespan, particularly when protected with overprint clear on screen prints. PVC signs, also known as Sintra Board, provide a cost-effective and durable option suitable for both indoor and outdoor use. They are more durable than Coroplast but less expensive than Dibond.

While Dibond signs are more expensive than Coroplast and PVC, the investment may be justified by their longevity and performance. Dibond signs, though less rigid than solid aluminum and relatively expensive, offer a high-quality print surface and are both water-resistant and recyclable.

Cost-effectiveness

Despite comparatively higher initial expenses, Dibond signs are a cost-effective signage option in the long term, due to their longevity and minimal maintenance requirements.

Real-Life Examples and Testimonials

Real-life examples and testimonials bring us closer to the impact and satisfaction Dibond signs have brought to their users. A customer on Amazon praised a Dibond aluminum no soliciting sign for being well made, sturdy, with clear, and easy to read printing, giving it a five-star review.

Summary

In conclusion, Dibond signs offer a unique blend of durability, lightweight properties, and premium aesthetics, making them a superior choice for both business and artistic applications. Their high customizability, weather resistance, and impressive lifespan make them a worthwhile investment for any business looking to make a lasting impression.

Frequently Asked Questions

What is dibond signage?

Dibond signage is a rigid product with two metal faces and a plastic core, making it stronger than epanel and lighter than standard aluminum.

What is the difference between dibond and aluminum?

Dibond has a solid polyethylene core, making it less expensive but not as strong as standard aluminum. Aluminum signs are entirely metal and offer greater durability and strength.

Are dibond signs good?

Yes, dibond signs are a good choice due to their resilience and versatility, making them suitable for various applications.

How long do dibond signs last?

Dibond signs can last for decades indoors and more than 5 years outdoors with proper care, thanks to the waterproof and durable characteristics created by its aluminum and plastic combination.

Can Dibond signs be customized?

Yes, Dibond signs can be highly customized in terms of shape, size, color, finish, and installation options.