One of the primary concerns in any industrial automation unit is ensuring the safety and reliability of data — preventing unauthorized access, cyber-attacks, and disclosures. Apart from keeping your information safe and sound, data security also improves the overall efficiency of the unit. Since industries increasingly rely on automation today, with the market expected to grow at a CAGR of around 9% by 2025, the need for reliable data storage solutions is at an all-time high.

This is where industrial Solid State Drives (SSDs) come in, offering a secure option for data storage in factories and warehouses. In this blog, we will walk you through the distinctive features of industrial SSDs and what sets them apart.

Advanced Features of Industrial SSDs for Automation

1. Enhanced Data Security

An industrial SSD uses a bunch of hardware-based encryption methods to enhance data security. Among these, one of the key mechanisms is the use of an Advanced Encryption Standard (AES), which is a symmetric encryption algorithm. AES works on a 256-bit key to encrypt and decrypt data, dividing it into 128-bit blocks. This powerful encryption ensures that your industrial SSD maintains a high level of confidentiality and the data is kept safe from breaches.

Other security features used in an industrial SSD are:

- Full-disk encryption (FDE)

- Self-encrypting drives (SEDs)

- Trusted platform module (TPM)

- Secure erase and drive locking

2. Superior Reliability

Industrial automation units often operate round-the-clock, which means that they require robust storage solutions that stand up to these environments. Consequently, an industrial SSD is programmed to run smoothly in harsh conditions, including electrostatic charges, dust, moisture, and high temperatures.

3. Data Integrity

Relying on error correction codes (ECC) and cyclic redundancy checking (CRC), an industrial SSD uses strong mechanisms to ensure the integrity of stored data. These help minimize error rates and maintain the accuracy of information stored on the drive, ensuring the information stored on your automation plant is accurate.

Complementing SSDs with DRAM Modules for Optimal Performance

Industrial SSDs and DRAM Modules

Industrial automation units often run data-intensive tasks that require seamless performance and operations — making traditional SSDs often fall behind in efficiency. In such settings, an industrial SSD is complemented with a DRAM module to accelerate the performance of automated units. With data mapping tables, these DRAM modules keep track of the logical blocks and their physical locations in the NAND flash memory. Such an efficient organization helps your automation plants retrieve data quicker, leading to faster, more responsive operations.

The Synergy: SSDs and DRAM

As a cache for industrial SSDs, DRAM is a temporary storage buffer. It helps you overcome the slow accesses associated with SSDs, ensuring that the data is available in no time when needed. This caching mechanism optimizes the data flow and minimizes latency, increasing the overall efficiency of the storage device.

An industrial SSD using a volatile memory like DRAM generally has quick data access speeds, usually less than 10 microseconds. This is crucial in industrial automation plants that necessitate rapid performance and data processing.

Choosing the Right DRAM Module

Choosing the right DRAM module for industrial automation systems is the key to ensuring reliable and efficient operations. Here is how you can choose the right one for your unit:

- Look for a DRAM module that runs within the specific temperature range of your system

- Choose a module with error correction (ECC) and a high number of program/erase cycles

- Check the power consumption requirements of the DRAM module

- Ensure that its data transfer rates align with the requirements of your unit

- Go for a module with sturdy construction and conformal coating

YANSEN’s SSD and DRAM Solutions for Industrial Automation

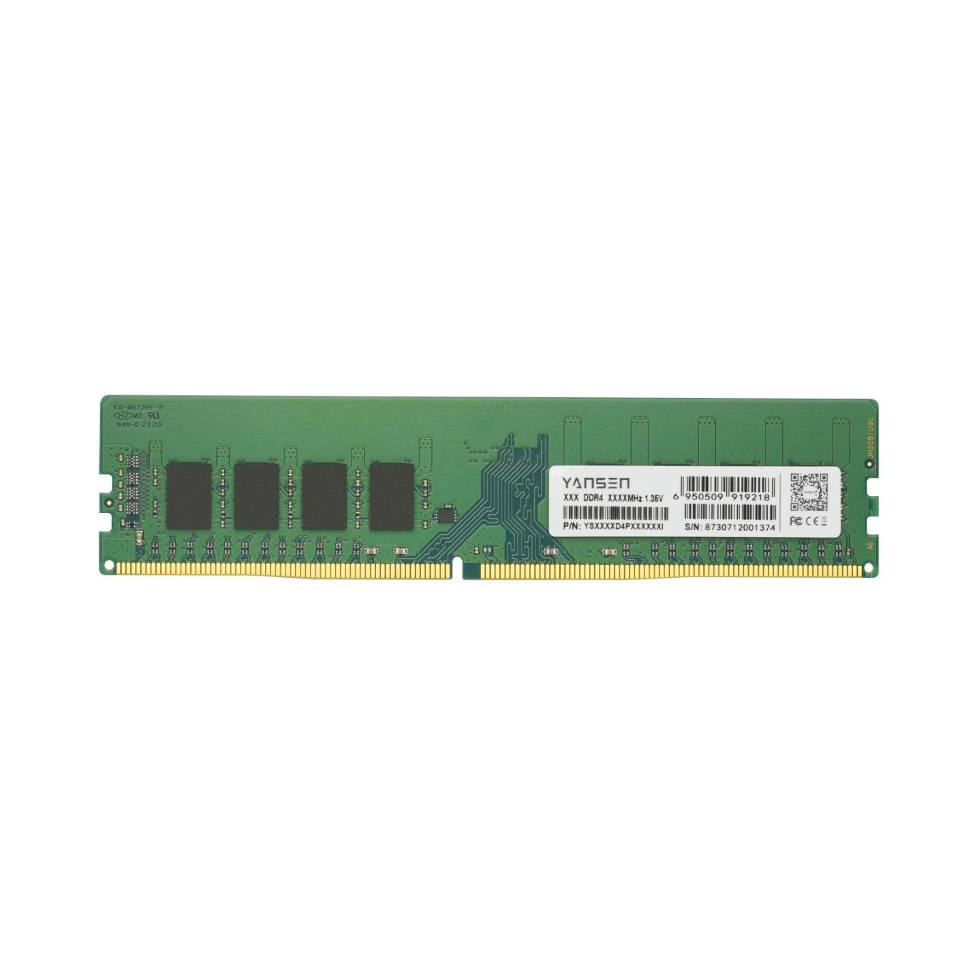

YANSEN offers a range of reliable SSD and DRAM industrial storage solutions tailor-made for automation. One of these is the YSXXXXD4PXXXXXXI, a high-speed DDR4 U-DIMM module that functions great even in demanding environments. Available in capacities ranging from 4GB to 32GB, with frequencies of 2666/3000/3200 MT/s, it is an answer to your industrial automation needs.

The module is based on 8 pieces of DDR4 SDRAM in different configurations, housed in an FBGA package on a 288-pin printed circuit board. This design facilitates stable and precise I/O data transactions on both edges of DQS. Consequently, you can expect flexibility for high-bandwidth, high-performance memory system applications.

In addition to the DDR4 U-DIMM, YANSEN provides DDR4 SODIMM solutions tailored for industrial requirements. These compact modules come in capacities ranging from 4GB to 16GB, with a 260-pin configuration, and operate at a frequency of 2666 MT/s.

Conclusion

If you’re looking for reliable, secure storage solutions for your industrial automation units, YANSEN is the one-stop shop. With programmable latencies and a range of operation frequencies, their storage modules are suitable for all industries that require high bandwidth and performance. No matter the industry you operate in, YANSEN has an industrial storage solution tailored just for you (and your operations).

Reference

[1] Size of the global industrial automation market from 2020 to 2025. Available at:

https://www.statista.com/statistics/1219772/industrial-automation-market-size-worldwide/ (Accessed: January 30, 2024)

[2] Solid-state drive. Available at:

https://en.wikipedia.org/wiki/Solid-state_drive (Accessed: January 30, 2024)