The world of concrete is constantly changing at a rapid pace, and the main driving force behind this change is one, technology is just getting better and two, that people want a bigger emphasis on sustainability. New discoveries and innovations like self-healing materials, 3D printing, and carbon capture are really changing the way concrete is made and used.

These new inventions are pretty promising and create concrete that is more durable, efficient, and concrete structures that are more environmentally friendly. Let’s take a closer look at some of these concrete advancements.

Self-Healing Cement: Cement Reinforcement

Self-healing concrete is designed to close its own cracks, extend the lifespan of buildings, and conserve resources by restricting the amount required for upkeep. This is achieved by the presence of agents such as microcapsules containing healing agents or microorganisms that release minerals, which seal the cracks upon their formation. Multiple recent tests confirmed the efficiency of self healing concrete throughout the lifespan of the concrete.

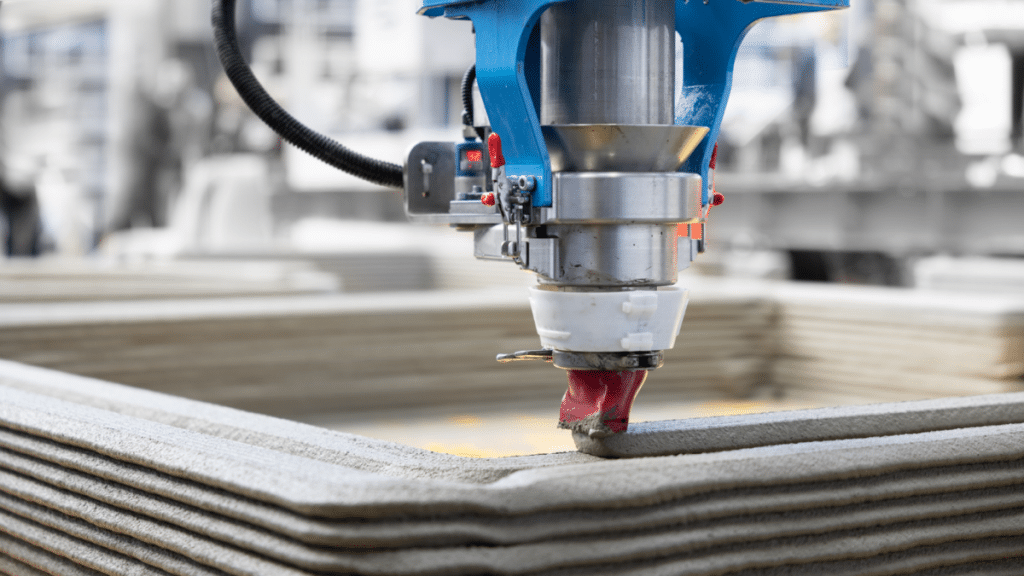

3D printing: Revolutionizing Building

The advent of the latest concrete industry, 3D printing can make printing complex structures possible with high detail levels and less material loss. Back in 2024, there was actually a concrete contractor who built the very first 3D-printed house in Latin America and they built all of the walls in just 29 hours. Using the 3D printing method dropped the overall time that it took to build the home and gave the builder more creative control over the design.

Carbon Capture and Environment Friendly Practices

Addressing the contribution from the cement manufacturing sector towards CO₂ emissions, the industry is also exploring the adoption of the carbon capture technique and storage (CCS) method. For example, a facility in Norway is actually using the CCS technique for the very first time ever for the sole purpose of severely limiting how much carbon dioxide they’re releasing by capturing the CO₂ and storing it under the seafloor.

Smart Concrete: Smart Integration for Structural Monitoring

Smart concrete incorporates the addition of sensor embedding for ongoing measurement of parameters such as stress, temperature, and humidity. This internet-of-things (IoT) application is for predictive building upkeep and enhanced security and longevity. Work during the recent past has focused towards the enhancement of longevity and the sensor embedding precision.

Sustainable Mix Designs: Reduction of Carbon Print

Innovations in mix designs such as the incorporation of alternate binder and recycled materials will make concrete manufacturing environment friendly. Companies are developing the cement releasing up to 85% less CO₂ through the use of alternate materials and processes. These environment friendly processes are gaining momentum as the sector is set for less environmental strain.

Conclusion

The integration of all the emerging innovations is forcing the concrete industry towards the direction of efficiency and sustainability. Embracing innovations like isolation of carbon, environment-favorable mix designs, intelligent monitoring systems, 3D printing, and healing materials is not only making the structures stronger and durable but also environmentally friendly by far. These innovations, through ongoing improvement, can potentially shift the built environment in more environmentally stable and profound ways.