All equipment should be at its best, with reliability and long life in all industrials for smooth running of operations. Of all the important components, bearings keep machinery running accurately, and one of the most popular choices in use today by many industries is the NTN Non-Contact Seal Bearing, which enables them to avoid contamination and extend the equipment’s lifespan. But how does it work? How do these bearings model a solution to machinery protection? This article explains how the NTN Non-Contact Seal Bearings can prevent contamination and add longevity to your machinery.

What is an NTN Non-Contact Seal Bearing?

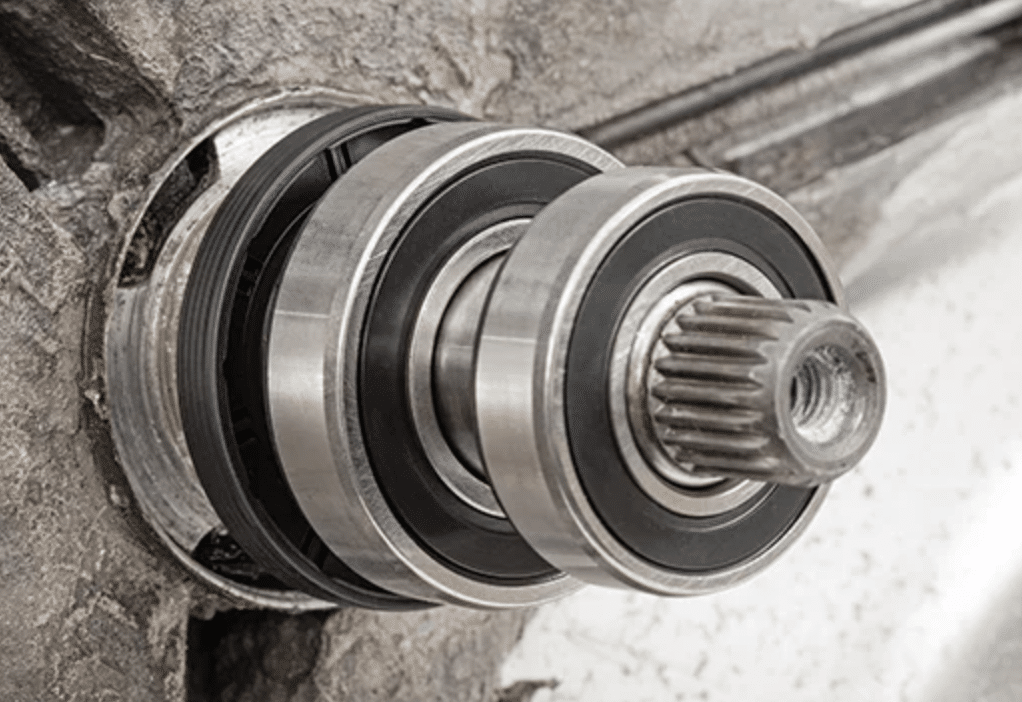

NTN Non-Contact Seal Bearings are designed such that the seal inside them will never contact the bearing surface. For the majority of the bearings, the seal will be in direct contact with the bearing race, but in the case of the non-contact seal bearing, there will be a minute gap in between. Thus, the probability of dirt, dust, and moisture or all such types entering into the bearings becomes very small. Further friction and wear reduces to a greater extent.

This special construction of the non-contact seal works by design to be a very effective barrier against environmental elements and is thus very apt for those industries where huge consequences could occur in case contamination should occur. In this way, the bearing is allowed to operate with smoothness, without any additional friction that could possibly be responsible for its premature wear or failure.

Non-Contact Seals to Avoid Contamination

Contamination is high on the list of causes of bearing failure. A tremendous amount of dirt, dust, and moisture, as well as other particles, easily enters a bearing and causes a great deal of internal destruction. Where classic contact seals usually work quite successfully, they do wear out eventually with use and lose their seal. NTN Non-Contact Seal Bearings are designed to shut out contaminants thanks to their improved sealing mechanism.

A non-contact design minimizes friction between the seal and the bearing to make sure the seal will last long and not deteriorate rapidly from constant contact. This means the seal remains intact through the lifetime of the bearing for its protective barrier against contaminants.

Besides, the NTN Non-Contact Seal Bearings are also very handy under high levels of dust or moisture. Most commonly, it has been in use in manufacturing plants, farm equipment, and even automotive systems where dirt and water can easily enter and quickly damage conventional bearings. The keeping out of contaminants raises the reliability of the bearing and extends operating periods of equipment.

Friction Reduction and Wear

Major advantages of these seals from being non-contacting include enormous reductions in friction. Since conventional bearing seals always come into contact with the bearing surface, in return it will cause friction, friction leads to heat and wear and maybe a source of failure, NTN Non-Contact Seals reduce this problem by allowing a small gap between the seal and the bearing surface.

This will reduce friction, hence heat generated; the surrounding would be cooler to this end when working. Less friction would further mean less wear on the bearing; thus, it prolongs the life of both the bearing and that of the equipment. Quite important, especially for machinery operating under high speeds or heavy-duty conditions, friction may turn out to be a big concern. In this respect, it minimizes wear to allow smoother operation that helps avoid problems like early failure with the NTN Non-Contact Seal Bearings.

Long Life of Equipment

NTN Non-Contact Seals Bearing helps avoid ingression of contamination while at the same time reducing frictional losses to add to the reliability and lifespan of machinery and equipment in general. This warrants the good performance of such machinery for longer periods since they protect the integrity of the bearing.

Among those industries with very high expenses and losses of productivity due to it is major equipment downtime. NTN Non-Contact Seal Bearing minimizes the frequency of failure and maintenance of the bearing, hence improving rotational efficiency in operations and reducing stoppages in production schedules.

These bearings have been designed to bear really high temperatures and harsh chemicals, thus being fit for many different types of industries-manufacturing, automotive, agriculture, and many others. It’s versatility combined with strength enables these bearings to be a highly dependable product in bringing an increase in life and performance.

Cost-Effective Solution

Although more expensive to buy than standard bearings, the benefits gained from NTN Non-Contact Seal Bearings quickly pay for themselves. Fewer bearing failures mean fewer maintenance costs and fewer overall replacements, which is how NTN bearings can help save company money since these bearings protect against contamination and wear, therefore avoiding frequent replacement of parts and costly downtimes.

NTN non-contact seal bearings are super-effective in equipment service life and contamination prevention. Construction guarantees the least friction coefficient that clears away contaminants, hence assuring smooth, more stable operation. Integration of such bearings into a system would contribute to machinery performance increases, longer machinery life, and security from low maintenance costs, and assurance against fewer production losses for the enterprise. From manufacturing to process, from agricultural to automotive industries, NTN Non-Contact Seals Bearings represent the intelligent, robust way of running smoother and more efficiently.