IT hardware emits a lot of noise during functioning. Noisy work can distract employees if server racks are placed in business offices or public places. That is why server cabinets are usually placed in other rooms. But what to do if there is no opportunity for arranging a separate data center? The use of a soundproof server cabinet comes as an alternative option.

Outwardly, this is a standard cabinet with a metal enclosure. However, its body is additionally insulated with sound-proof materials to eliminate the level of noise. This solution has the following benefits:

- Absorb noise. Network equipment works noisily. A special body design allows for reducing the level of noise.

- Achieve ideal server room temperature. An additional layer of sound-proof material allows maintaining the required environmental conditions. By absorbing noise, materials also can regulate the temperature. Thus, they can improve options with active and passive cooling and ensure smooth system running.

- Save space. Server furniture is multi-level, which allows accommodating a great number of network hardware occupying several square meters of a room.

- Easy and quick setup. No special knowledge or skills are required to assemble a furniture piece and arrange the system.

- Improve server acoustics. Due to noise reduction, a quiet server rack, for example like here, is perfect for installation in crowded places, offices, and other premises where people work.

The Technologies Used and the Soundproofing Principle

Modern manufacturers use several technologies to soundproof furniture. They are divided into active and passive ones.

Active measures include the so-called “Active Structural Acoustic Control” technology. The method implies the attachment of piezo ceramic elements to the body parts, which directly counteract the emerging resonances. An adaptive control system causes response vibrations and thereby significantly weakens the general vibrations of structural parts.

Return echo creation is another method for reducing the noise level. In the simplest version, a system consisting of a microphone, a loudspeaker, and a control module is applied. The microphone records the emerging noises, and the control module analyzes them. Then, the input signal is amplified, inverted in phase, and output through the loudspeaker.

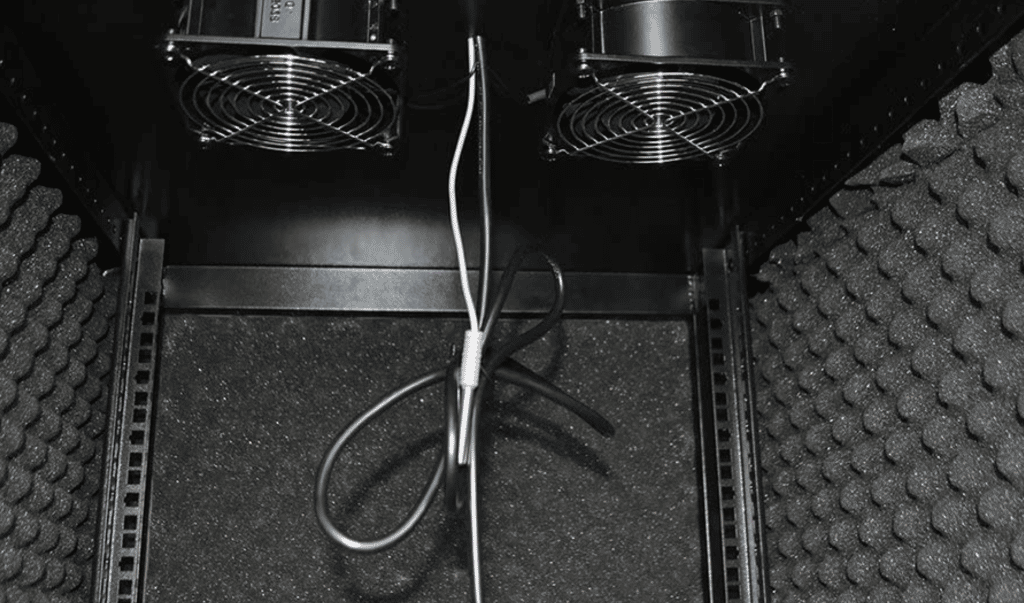

Reducing the level of noise through passive methods is the simplest and cheapest method. In particular, only as many fans as actually required should be connected, and the control system should adjust their rotation speed to the amount of heat generated.

Sheathing cabinet walls with noise-eliminating materials is another means. This method is ideal for suppressing mid and high frequencies. The degree of sound absorption depends on the type of material, its thickness, method of fastening, and surface structure. In addition, fans and individual modules must be mechanically separated from the cabinet using blanking plates.

6 Steps to Make Server Furniture Quieter DIY

Skilled employees can soundproof server enclosure and make it work quieter. To cope with the process on your own, follow the guide:

- Select an appropriate material. Several materials are usually used to eliminate noise. Decide which one you want to use.

- Consider cable management and cooling issues.

- Look through the cabinet specifications to find out the dimensions of your furniture.

- Cut the material according to these dimensions to fit side panels and doors.

- Apply special wood glue to reliably attach the material to the cabinet enclosure.

- Additionally, you can apply nails to secure the construction when wooden materials are used.

- When all the panels are soundproof, assemble panels and install the product. You’ll need screws and a screwdriver.

Materials to Soundproof Server Furniture

Due to acoustic characteristics, the following materials are the best ones for reducing extra noise during hardware operation:

Mass loaded vinyl

A dense material is characterized by perfect qualities in terms of sound reduction. It was used to soundproof surfaces of industrial facilities. Although it is a thin material, it absorbs extra noise. Due to its flexibility, it is possible to customize the material as you need. It is also resistant to heat.

Mats for noise deadening

This is a kind of mass loaded vinyl developed for the auto industry to provide a sound barrier in cars. System administrators use it for enhancing the enclosures of data center furniture. It is possible to shape the piece to any surface. To achieve the maximum sound barrier, it is possible to glue several layers of mats.

Rubberized undercoating spray

This is a special compound spray applied to metal surfaces of server racks. When the substance dries, it forms a thin rubber layer that perfectly adds mass to side panels and dampens sound. This option not only provides a sound barrier but also protects surfaces from corrosion, rust, and moisture.

But note that the spray application required drying for a long time. When the substance is applied, it is necessary to leave the product for a few days to let it dry.

Acoustic foam

This solution serves to muffle sound, but when it is used alone, noise reduction is not sufficient. Thus, it is advisable to apply form in a combination with other materials as a supplementary tool. An indisputable advantage of foam is its resistance to rust and heat.

The need for quiet network and server cabinets in enterprises arises if they have to be placed in or near office premises. We are talking about open office spaces, conference rooms, or other public locations. Noise prevents employees from concentrating on important matters and reduces work efficiency. In such cases, quality noise-barrier furniture helps eliminate the level of noise and cope with the problem.