Precision mould parts are pivotal across diverse industries, from automotive and electronics to medical devices and consumer goods. These components, produced through plastic injection moulding, boast intricate designs and tight tolerances, contributing to end products’ overall efficiency and quality. In the realm of manufacturing, the selection of a reliable precision injection moulding company is paramount.

The success of any project hinges on the precision and reliability of the moulds used in the manufacturing process. As such, carefully considering a mould manufacturer becomes critical in ensuring the production of high-quality and consistent precision mould parts.

Applications of Precision Moulding

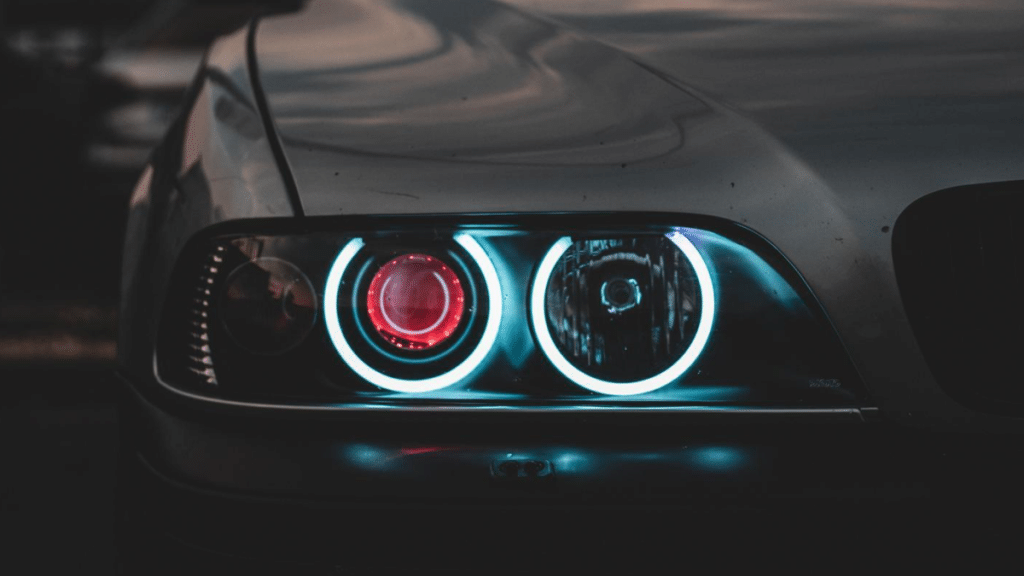

- Automotive Industry: Precision moulds are indispensable for creating intricate and accurately shaped components in the automotive sector. These molds manufacture various automotive parts, including interior features, dashboard elements, exterior panels, and precision-engineered engine components. The automotive industry relies heavily on the precision moulding process to ensure its vehicles’ durability, functionality, and aesthetic appeal.

- Medical Device Manufacturing: In the medical field, precision-molded parts play a critical role in producing medical devices and equipment. This includes components for diagnostic devices, surgical instruments, implants, and drug delivery systems. The strict regulatory standards and the need for precision in medical applications make the selection of a reliable precision injection molding partner crucial to ensure the safety and effectiveness of these devices.

- Electronics and Technology: Precision moulding is essential in the electronics industry for creating intricate and small-scale components used in electronic devices. This includes connectors, housings, micro-components, and other parts critical to the functionality of devices like smartphones, computers, cameras, and audio equipment. The precision moulding process ensures that these components meet the tight tolerances required for optimal performance in electronic applications.

How Do You Choose a Reliable Precision Injection Molding Manufacturer?

When selecting a reliable precision injection molding manufacturer, consider these factors:

- Certifications: Look for precision injection molding manufacturers with relevant certifications, such as ISO 9001 for quality management systems. Certifications indicate a commitment to adhering to international standards and best practices.

- Experience: A reliable precision injection molding manufacturer should have a substantial track record in the industry. Assess their knowledge by reviewing their portfolio and examining case studies relevant to your industry. Consider the complexity and diversity of projects they have handled in the past. A manufacturer with a proven history of successful projects is more likely to provide consistent quality and meet the specific demands of your molding requirements.

- Precision Moulding Capabilities: Evaluate the manufacturer’s precision moulding capabilities, including the technology and equipment they utilize. Cutting-edge machinery and advanced molding techniques contribute to achieving tight tolerances and producing high-precision components. Request information about the types of molds they specialize in and their ability to handle complex geometries, multi-cavity molds, and various materials relevant to your project.

- Research and Development (R&D) Ability: An effective precision injection moulding manufacturer should intensely focus on research and development. This capability ensures that they stay abreast of the latest advancements in molding technology, materials, and process optimization. Manufacturers with robust R&D capabilities are better equipped to offer innovative solutions, address unique challenges, and continuously improve their processes for enhanced efficiency and quality.

- Customer Support: Assess the level of customer support provided by the precision injection molding manufacturer. Effective communication and collaboration are crucial throughout the molding process. A reliable manufacturer should be responsive to inquiries, provide clear project updates, and offer proactive solutions to potential challenges. Strong customer support contributes to a smoother collaboration and meets your needs and expectations.

If you are looking for a reliable precision plastic injection molding company that boasts all qualities, including custom plastic molding, consider WOKA, as it stands out as a trusted partner committed to delivering high-quality and innovative solutions tailored to your specific needs.

WOKA

WOKA is one of the leading plastic injection mold companies in China with over 18 years of industry expertise and stands at the forefront of precision mould production. Since its establishment in 2005, WOKA has been committed to delivering exceptional quality and innovative solutions to various industries, including automotive, medical, electronics, and more.

The company’s entrepreneurial spirit revolves around dedication, honesty, teamwork, and innovation. With years of experience and professionalism, WOKA is a reliable partner of Audi, BMW, Mercedes-Benz, Rolls-Royce, and other famous car brands.