Not every place to stay has a socket ready. The electricity storage often limits the length of stay. A modern lithium battery promises longer self-sufficiency. This must be taken into account during installation.

Lithium RV batteries have become an indispensable part of our everyday life. They first appeared as small button cells in wristwatches, then as storage for power-hungry smartphones and laptops, and now even as fuel for electric cars. Demands are also growing in mobile homes, more and more consumer appliances are draining the electricity storage system, and the convenience of operating a 230-volt device via an inverter is appreciated.

Lots of power capacity thanks to the lithium battery

Instead of adding a second or third lead-acid battery, the question is increasingly being asked as to whether a lithium battery would not be a better choice. The prices are still many times higher than for a lead gel or AGM battery of the same “size,” i.e., the number of ampere-hours. However, consider that the usable capacity of a lithium battery is about twice as high, and the number of cycles is even three times or more. In that case, the acquisition costs are not necessarily higher over the entire service life.

Of course, the lithium battery also has to be charged. Aside from the shore power socket, a solar panels system, a generator, or the engine of the base vehicle are the main options for this. Anyone who likes touring around the country could replenish their power reserves every time they continue their journey. But modern engines don’t go along with that because they are trimmed to minimize CO2 emissions. This is where intelligent alternators come in, switching off the current flow as soon as the starter battery is full – even if the onboard battery still needs charging.

This can be remedied by so-called charging boosters, which take care of better charging performance for the auxiliary battery on the go. If it is a fast-charging lithium battery, it is worth working with massive booster power, which promises a largely full charge even on medium-long journeys.

The optimization shown here follows this idea. The standard 95 Ah AGM lead battery is replaced with a 200 Ah Renogy lithium iron phosphate battery and supplemented by two Victron charging boosters, each with a charging current of 30 A. To charge the LPF battery as quickly and optimally as possible on shore power, it would also be necessary to replace the electro black or add a second charger with a lithium characteristic. However, in the Etrusco long-term test car, we deliberately leave it at the scope above to test how far you can get with it.

This must be taken into account during the installation

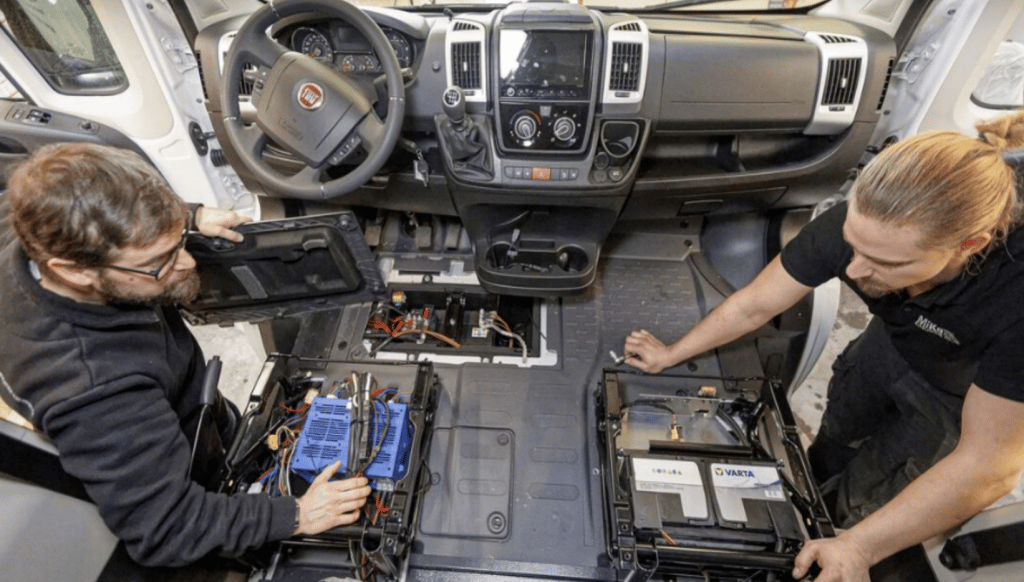

The team from Mika Caravan in Dinkelsbühl completed the installation in around four hours. Depending on the installation situation, it can also take longer than here, where only short cable routes had to be laid inside the driver’s cab. Installation costs can vary between around 600 and 800 euros.

The arrangement of the onboard electrical components shown in the seat consoles of the Fiat Ducato is very common in entry-level and mid-range motorhomes. For this purpose, Renogy has two LFP battery models with 150 or 200 Ah in its range, the dimensions of which are specially tailored to the seat consoles. The space in the console is just enough for the two charging boosters to be installed next to them so that the line paths remain short with low losses.

Even if the 12-volt direct current installation technology is relatively harmless, it is advisable to leave the conversion to a specialist workshop. After all, currents of up to 60 amperes flow, so not only do the cable cross-sections have to be chosen carefully – here, 16 mm2 cable – but also the ends have to be screwed together permanently vibration-proof. For this purpose, eyelets are pressed onto the ends of the assembled cables with a special tool, and the insulation is stripped with shrink tubing.

Removing all trim parts from the seat consoles and, ideally, also the seats creates space for working. To do this, however, the cable connections of the seats have to be disconnected and later reconnected – a process that should be reserved for the specialist staff because of the pyrotechnic belt tensioners.

A D+ control line is also placed next to the two thick positive lines that lead from the boosters to the starter battery, which reports when the engine is running – only then do the boosters start their work. There is often a suitable terminal near the electrobloc or charger where the booster’s control line can be connected. The refrigerator also needs this signal if it is equipped with an automatic energy source selector. If the existing charger – here a Schaudt EBL 31 – does not have a characteristic curve for lithium batteries, one selects the one for lead-gel batteries because the final charging voltage of 14.4 volts is better for LFP batteries.

The Renogy battery and the Victron booster have an integrated Bluetooth module and can be controlled via an app. Not only can all relevant status values of the battery be read directly, but various booster settings can also be specifically adapted to the situation. These are also good prerequisites for testing the suitability of this solution for practical use over the next few months.