Forklifts are essential equipment for material handling in various industries, from warehousing and manufacturing to construction and transportation. These powerful machines rely on a crucial component – the forklift battery. Understanding forklift batteries is vital for maximizing efficiency, minimizing downtime, and ensuring a safe working environment. This comprehensive guide will delve into the world of forklift batteries, covering their types, selection criteria, and the benefits of Great Power’s innovative solutions.

Importance of Forklift Batteries in Material Handling

A forklift battery is a specialized power source designed to provide the energy needed to operate a forklift. It acts as the heart of the machine, powering the electric motors that lift, lower, and move heavy loads.

Forklift batteries are crucial for efficient and reliable material handling operations. They enable:

- Increased Productivity:Electric forklifts powered by batteries offer smooth and quiet operation, allowing for faster and more efficient material movement.

- Reduced Emissions:Unlike combustion engine forklifts, electric forklifts powered by batteries produce zero emissions, contributing to a cleaner and healthier work environment.

- Improved Safety:Battery-powered forklifts operate quietly, reducing noise pollution and improving safety by minimizing distractions.

- Lower Operating Costs:Battery-powered forklifts often have lower operating costs compared to combustion engine counterparts, thanks to reduced fuel consumption and maintenance requirements.

Types of Forklift Batteries

The market offers a variety of forklift battery types, each with its own advantages and disadvantages. Here are some of the most common types:

1. Lead-Acid Batteries

Lead-acid batteries are the traditional and most widely used type of forklift battery. They are known for their affordability, reliability, and ease of maintenance. However, they also have some drawbacks:

- Heavy Weight:Lead-acid batteries are relatively heavy, which can limit the forklift’s lifting capacity and maneuverability.

- Limited Lifespan:Lead-acid batteries have a limited lifespan, typically requiring replacement every 3-5 years.

- Environmental Concerns:Lead-acid batteries contain lead, a toxic metal, posing environmental concerns during disposal.

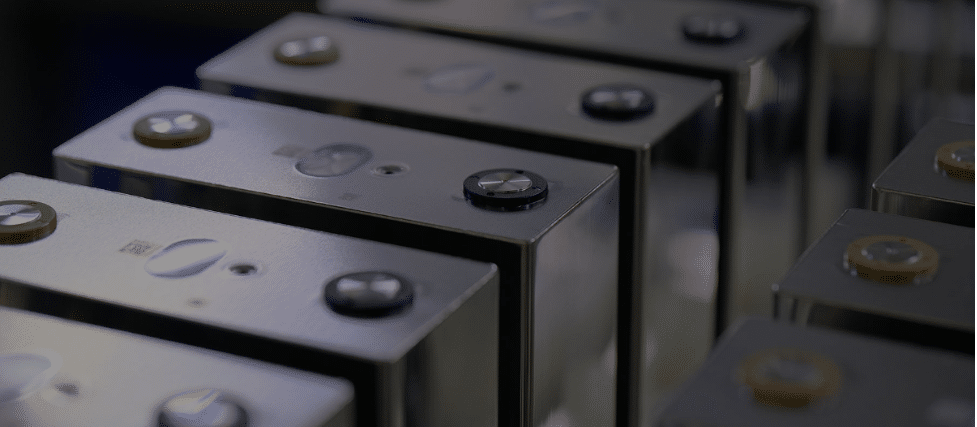

2. Lithium-Ion Batteries

Lithium-ion (Li-ion) batteries have gained popularity in recent years due to their superior performance and efficiency. They offer several advantages:

- Lightweight and Compact:Li-ion batteries are significantly lighter than lead-acid batteries, allowing for greater lifting capacity and maneuverability.

- Longer Lifespan:Li-ion batteries have a longer lifespan, typically lasting 2-3 times longer than lead-acid batteries.

- Faster Charging:Li-ion batteries charge faster than lead-acid batteries, reducing downtime and increasing productivity.

- Higher Energy Density:Li-ion batteries offer higher energy density, allowing for longer operating times on a single charge.

3. Sodium-Ion Batteries

Sodium-ion (Na-ion) batteries are a relatively new technology gaining traction as a more sustainable and cost-effective alternative to Li-ion batteries. They offer several advantages:

- Abundant and Sustainable:Sodium is a readily available and sustainable resource, making Na-ion batteries more environmentally friendly.

- Lower Cost:Na-ion batteries are generally cheaper to produce than Li-ion batteries, making them a more affordable option.

- Improved Safety:Na-ion batteries are considered safer than Li-ion batteries, as they are less prone to overheating and fire hazards.

Choosing the Right Forklift Battery

Selecting the right forklift battery is crucial for optimizing performance and minimizing costs. Here are some key factors to consider:

1. Capacity and Power Requirements

The battery’s capacity and power output must meet the specific requirements of the forklift and its intended applications. Factors to consider include:

- Lifting Capacity:The battery needs to provide sufficient power to lift and move the intended loads.

- Operating Time:The battery should provide enough power for the required operating time without needing frequent recharging.

- Duty Cycle:The battery’s capacity should match the forklift’s duty cycle, which refers to the frequency and intensity of use.

2. Charging Infrastructure

The availability and type of charging infrastructure are crucial considerations. Factors to consider include:

- Charging Time:The battery’s charging time should be compatible with the operational needs and available charging time.

- Charging Method:Different battery types require different charging methods, such as AC or DC charging.

- Charging Station:The charging station should be compatible with the battery type and provide sufficient power for efficient charging.

3. Battery Compatibility

Ensure the chosen battery is compatible with the forklift’s electrical system and charging infrastructure. Factors to consider include:

- Voltage:The battery’s voltage must match the forklift’s electrical system.

- Dimensions:The battery’s dimensions should fit the forklift’s battery compartment.

- Connections:The battery’s connections should be compatible with the forklift’s charging system.

4. Cost-Effectiveness

Consider the total cost of ownership, including the initial purchase price, charging costs, maintenance costs, and battery lifespan. Factors to consider include:

- Initial Cost:Li-ion batteries are typically more expensive than lead-acid batteries, but their longer lifespan and lower maintenance costs can offset the initial investment.

- Charging Costs:The cost of electricity for charging can vary depending on the battery type, charging time, and local electricity rates.

- Maintenance Costs:Li-ion batteries generally require less maintenance than lead-acid batteries, reducing overall operating costs.

5. Environmental Impact

Consider the environmental impact of the battery type, including its production, use, and disposal. Factors to consider include:

- Resource Extraction:Lead-acid batteries require the extraction of lead, a toxic metal, while Li-ion batteries rely on lithium, which is a more sustainable resource.

- Recycling:Li-ion batteries are generally easier to recycle than lead-acid batteries, contributing to a more circular economy.

- Disposal:Proper disposal of batteries is crucial to minimize environmental contamination.

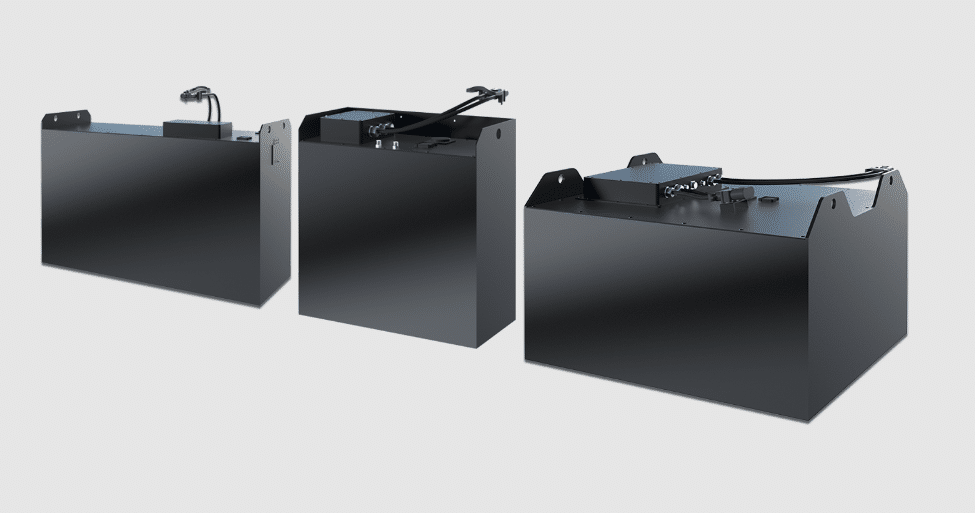

Great Power’s Forklift Battery

Great Power is a leading provider of innovative forklift battery solutions, offering a range of high-performance batteries designed to meet the demanding needs of modern material handling operations. Here are some key features of Great Power’s forklift batteries:

1. Lithium or Sodium

Great Power offers both lithium-ion and sodium-ion batteries, providing customers with a choice based on their specific requirements and budget.

2. Shock-Resistance

Great Power’s batteries are designed with robust construction and shock-resistant features to withstand the rigors of demanding applications.

3. Stable and Strong Current-Carrying Capacity

Great Power’s batteries are engineered to deliver stable and strong current-carrying capacity, ensuring consistent power output for reliable performance.

4. Enhanced Stability

Great Power’s batteries incorporate innovative technologies to enhance stability, minimizing vibration and impact during operation.

Conclusion

Great Power’s forklift batteries offer a combination of advanced technology, robust construction, and exceptional performance, making them an ideal choice for businesses seeking to optimize their material handling operations. Great Power is committed to providing innovative and reliable solutions for the material handling industry. Contact them today to learn more about their forklift battery solutions and how they can help you optimize your operations.