Introduction

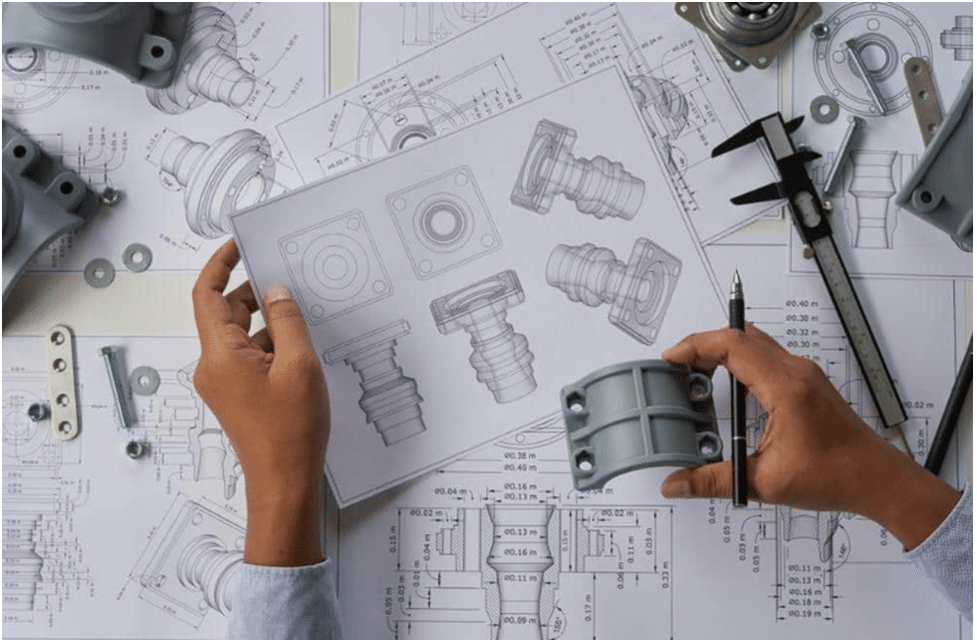

Technical progress always necessitates precision metal working as the fundamental factor of industrial machinery big names. In aerospace, medicine, and different industries, it is usually very precise and delicate tracing metal components into various small parts to help components work in its best performance. Mum by every torch and striking, Precision Metal Fabrication is just a metal piece of work that can technologies your tech through the means of varied artful expressions. It’s not so much recreation, as it is refinement, stretching limits inside of what’s available in the tech industry.

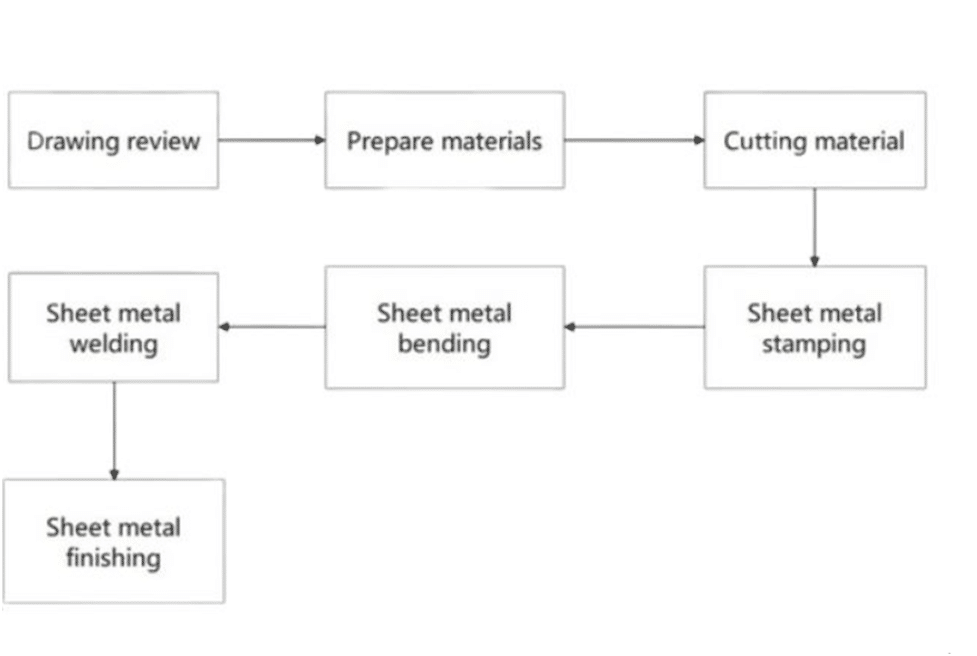

The Core Processes of Precision Metal Fabrication!

Cutting Quality

Laser

When it comes to proving technological machines, laser cutting is surprising by its high accuracy and speed. Modern fabricators obtain high-temperature CO2 or fiber laser cutting, revealing even 0.1mm thin sheets of metal. This is computer software that enables one to develop and visualize structures with complicated designs and tolerances hence suitable for the medical devices and aerospace industry.

Plasma

Plasma cutting is the technology that most contributes to the accuracy of the production of precision metal working jobs; it is useful when thicker metal is to be cut. It uses an electric splash and compressed air to melt down the metal. This tool, with the ability of cutting even up to 30mm thick material, is loved for the heavy duty applications, such as fast throughput.

Waterjet

Waterjet cutting, which goes beyond what can be achieved by laser or plasma cutting in terms of accuracy, is the number one technique in precision metal fabrication at the moment.

It operates under the water pressure of up to 5000 kg/cm2 (7000 psi) and often adjusted by abrasives, which allow it to cut materials up to 200mm in thickness. Well-suited for dealing with fused materials and the soft components where it creates only heat-affected zones, therefore, it prevents the final product from new flaws.

Forming Role

Bending

In precision sheet metal fabrication, bending of the flat sheets into V, or channel-shape is initiated to buttress the overall aesthetics of the work. Technicians run CNC press brakes, which angle profile 0.5-degree accuracy, for example. This is a tool frequently used by machine shops for curved metalwork, such as frames, brackets, and similar items like in construction and automotive industries.

Stretching

Stretching is the most significant part in precision metal fabrication because in this case, metal sheets with different lengths are produced, all of which have the same thickness.

This is necessary so that the given of equal strength is realized for spacecraft parts that require uniform strength. It is a stretching-based process, so aircraft skins and other parts of the car are being fabricated without any compromise on the material’s actual performance.

Press Brake

The press break is now the essential device in the precision metal fabrication industry, which brings unmatchable precision in bending metal. It offers an assortment of material-shaping options ranging from error tolerance to 0.5mm and 20mm respectively.

Without this added accuracy, errors will materialize around interfaces of enclosures and brackets which might not be able to cater for the increasing parallel demands from different industries.

Joining Techniques

Welding

With welding being the most fundamental welding metal formation method, two pieces are merged via fusion. Joining of varying thicknesses – 0.5mm to over 50mm – could be mixed effectively using TIG, MIG, and arc welding techniques by welders. The procedure of welding is essential in designing pipelines, cars and other structures so that they are maintainable and strong.

Riveting

Riveting, as a process, stands true to its power and is capable of True metal fabrication for joining the parts without using the hot melting. Leading rivets are commonly used for ‘sheet fastening’ and connection of structures and artifacts that comprise the bridges and aircraft, with vibration resistance and mechanical integrity as the main targets of such assemblies.

Fasteners

Fasteners are vital for their own sides of versatility and reversibility in accuracy metal fabrication. From 4 screws, we have bolts and also nuts from 1 mm length to over 100mm by the long one that helps in quick assembly and also disassembly. They are a core part of the machine, electronics and auto creating where the maintenance and adaptability are necessarily.

| Process | Method | Key Feature | Material Thickness (mm) | Precision (±mm) | Speed (m/min) | Ideal Application |

| Cutting | Laser | High Precision | 0.5 – 25 | 0.1 | 10 | Intricate Designs |

| Plasma | High Speed | 1 – 50 | 0.5 | 20 | Thick Metal Sheets | |

| Waterjet | No Heat Impact | 0.5 – 200 | 0.25 | 7 | Mixed Materials | |

| Forming | Bending | Angle Accuracy | 0.5 – 30 | 0.5 | N/A | Frames, Enclosures |

| Stretching | Uniform Strength | 0.5 – 100 | N/A | N/A | Aerospace Parts | |

| Press Brake | Custom Angles | 0.5 – 20 | 0.1 | N/A | Precision Bends | |

| Joining | Welding | Strong Bond | 0.5 – Over 50 | N/A | N/A | Structural Components |

| Riveting | Mechanical Join | N/A | N/A | N/A | High-Vibration Parts | |

| Fasteners | Reversible | N/A | N/A | N/A | Easy Assembly |

Table on The Core Processes of Precision Metal Fabrication!

The Cutting Edge: Advanced Fabrication Techniques!

Laser vs. CNC

Precision

The title is divided into two sentences. The first one will be dedicated to the top feature of laser cutting in precision metal fabrication – the precision. The second sentence will emphasize the accuracy of laser cutting. CNC machining also is popular due to its technological versatility as it is capable of working with tolerance ranging from around 0.05mm, thus, it is the most preferred for the complex and three -dimensional parts. Both of the techniques remain the means to all ends despite dissimilar characteristics making one stand out over the others.

Speed

Laser cutting is rapid in operation as it is able to cut through materials at a rate of 10 m per minute. Material thickness also plays a crucial role on how fast laser cutting can run.

With CNC machining with speeds up to 2m per minute now being in the forefront of the line, the technology works best for prototyping and intricate designs. Being able to select the most appropriate procedure should be of utmost importance as each of them is intended to guarantee efficiency of the production process.

Press Braking Evolution

Flexibility

Contemporary bend brakes, used in highly precise metal forming, are endowed with unmatched flexibility and allow yoto bend from 0.5mm to over 25mm. With flexible machined geometry and angle corrections, they are able to fit special bends. They can work for the manufacturing of automobiles and the aircraft industry with higher adaptability.

Accuracy

The advent of higher precise metal fabrication in press braking technology has made a more preferable accuracy in the press braking. Today, the models manufactured achieve bending with a variation of less than 0.1 degrees, an essential parameter for high-field specification items. Through this technological outbreak, uniformity and accuracy is accurate in all bandings.

Turret Punching Impact

Efficiency

Shooting from turret-like devices provides accuracy and quickness in the stamping process of metal sheets as large as 3m x 1.5m at 600 hits per minute. Hence, it is recommended for high speed production and produces several perforations and intricate designs that are tending to be produced in a single tool without the need to change it.

Consistency

Certainly, Turret punching impresses for being the most reliable method in the reproducibility of the metal fabrication while being precise. And owing to the fact that it can ensure repetition and uniformity in the large parts, it then means that it is a basic requirement in projects that do demand higher equalization. The trend of increasing digitization also flows with the core principle of consistency which is essential in the industries where precision is not simply an advantage but a must.

Material Matters: Choosing the Right Substance for Fabrication!

Influence of Properties

Strength

Strength is a basis in precision metal forming, a factor that tells us how a material of a given material can withstand force or deformation. For structure, components such as the steel and titanium grade which perform best under pulling and pushing stresses are mostly used in the automotive and aerospace industries.

Durability

Resilience is such that subjection to tear, vaporization and load outlasting capability are thought to be very long. In the case of precision metal fabrication, we make sure that we select Stainless steel and coated alloys that guarantee long service lives. What is vital in marine-medical and outdoor applications related to sustainability, is the use of the durable materials for resilience of the devices to most adverse conditions.

Optimal Material Selection

Stainless Steel

Corrosion resistance, longevity, and strength are paramount qualities exhibited by stainless steel – being a material in-demand in precision metal fabrication. It can also be used in the fabrication of medical equipment, food processing equipment and architecture that will provide a combination of durability, attractive finishes and needs less maintenance cost.

Aluminum

One of the properties that project aluminum as suitable for aviation is the lightweight and resistance to corrosion. It is thus used in precision metal fabrication by the automotive as well as aerospace industries. Thanks to its flexibility, the metal enables the development of complicated ornamentation, whereas lightweight gives impetus to the manufacture of cars and airplanes that burn less fuel.

Titanium

Titanium, which is to be commended specifically for its impressive strength and capability to resist both corrosion and high temperatures, is perfectly matched to challenging precision metal fabrication applications for aerospace and medical implants. Regardless of high cost, of course, its quality and lightweight properties stand as strong recommendations when performance-based applications or projects are considered.

| Property | Stainless Steel | Aluminum | Titanium |

| Strength | High | Moderate | Very High |

| Durability | Very High | High | Extremely High |

| Weight | Heavy | Light | Lighter |

| Corrosion Resistance | Excellent | Good | Exceptional |

| Cost | Moderate | Lower | Higher |

| Weld ability | Good | Excellent | Moderate |

| Applications | Medical devices, architecture, food processing | Aerospace, automotive, packaging | Aerospace, medical implants, sports equipment |

Table on Material Matters: Choosing the Right Substance for Fabrication!

Real-World Applications: Where Precision Metal Fabrication Shines!

Indispensable Industries

Aerospace

The space travel industry uses hard tooling and will tolerate only short time delays apart from occasional problems that could have serious repercussions. Under incidence of intense pressure and temperature, alloys are processed to form finite components. Every succeeding component starting from engine parts to all the structures inside must pass through the strict high set of standards for safety and performance.

Automotive

Automotive manufacturers use such accurate metal fabrication both for structural integrity and decorating. From the chassis assembly to engine creation parts, the high-precision cutting, bending and fitting ensures all the vehicles are built with higher levels of durability, safety and efficiency.

Medical

Delicate metal fabrication plays an important role in the medical industry, which enables building instruments, implants and systems that work with high-precision. Stainless steel and titanium due to their biocompatibility and endurance characteristic are the popular materials, enabling titanium’s lasting performance alongside patient safety.

Transformation in Sectors

Innovation

Influence of precision metal fabrication supports innovation, as a result of which difficult, high-production parts are being created. Sophisticated implementations such as laser cutting control allow products to achieve radical breakthroughs making all the industries progress deeper worldwide.

Customization

Transformability is every integral process of manufacturing in precision metal fabrications. Each sector requires a unique response and we offer specific services from prototyping to production to fulfill their needs. The adaptability in this is an advantage in such industries such as aerospace and medicine where personalized parts often are present.

Scalability

Metal precision parts scalability makes it possible for industries to switch from small amounts to large amounts of production without loss in quality. It is an essential element in industries such as automotive design that are affected by realizing the changing market demand and optimizing production systems.

Conclusion

Taking into account all the things said, it’s time to wrap it up as we can all perceive that Precision Metal Fabrication is not only a process but rather a forefront of technology emerging. Managing to turn into complex parts from raw materials is its strong side. It is based on a breakthrough of anything so its essential functions stabilize. Precision machining metal fabrication, then, should be regarded as more than just a method; it is that foundation upon which the developing technologies will rely on completely (they should not only tend to meet but also fulfill the tough requirements of tomorrow’s world).