Tri-clamp fittings are a popular choice of connection for pipelines and equipment in the food and beverage industry, thanks to their unique characteristics. Also known as sanitary fittings or clamp fittings, tri-clamps play a key role in making the sanitary connection leakproof and easy to clean. Their hygienic design and simple mechanism of connection provide an ideal solution for applications where contamination risks are a concern. Some of their other advantages include their leakproof sealing capabilities, ease of assembly and disassembly, and versatility for joining different pipe materials and equipment.

Tri-Clamp Fittings – Overview and Features

A tri-clamp fitting, sometimes called a tri-clover fitting, is a type of quick disconnect fitting that utilizes a unique three-bolt clamping design. The popularity of tri-clamp fittings comes from their versatility in connecting pipes, hoses, tanks, and other equipment commonly used in food manufacturing and processing applications. Some key features that make tri-clamp fittings preferable include:

1. Hygienic Design

Tri-clamp fittings feature smooth surfaces without crevices where bacteria can grow. Their hygienic design meets 3-A sanitary standards and FDA requirements, making them ideal for food processing applications. The faces of the clamp join together perfectly to prevent residue accumulation.

2. Ease of Cleaning

Tri-clamp fittings can be disassembled without tools, allowing all surfaces to be easily cleaned and sanitized. Their simple design does not have openings or threads where debris could become trapped. All surfaces are accessible for thorough cleaning.

3. Leakproof Seal

When the tri-clamp is properly closed, it compresses a rubber gasket between the mating surfaces, hence forming a tight seal to prevent liquid leaks. The seal is easily reestablished with each new connection.

How to Make a Tri-Clamp Connection

Making a connection using tri-clamp fittings is a straightforward process. You simply need to follow proper guidelines. The basic steps to connect tri-clamp fittings include:

1. Clamp Assembly

Loosen the three bolting clamps on each fitting piece by turning the wing nuts clockwise until fully loose. Inspect the rubber gasket pads inserted in each clamp to make sure they are intact, flat, and free of debris. Defective pads could impact sealing. Replace any worn pads before assembly for the best results. Clean mating surfaces if needed.

2. Face-to-Face Connection

Carefully bring the faces of the two tri-clamp pieces together. Apply gentle, even pressure so as not to cross-thread. A resilient gasket, usually silicone, should be neatly centered between the faces. Slowly compress the gasket as the faces make contact. Take care to perfectly align the three bolt holes so they precisely overlap with no gaps or offset. Proper alignment of holes is essential for subsequent tightening.

3. Gasket Sealing

Start tightening one set of clamps clockwise in slow, smooth rotations while applying pressure. Check compression periodically by gently pushing in on the clamped area. Tighten the next set in a logical sequence, such as the clockwise star pattern, until evenly torqued. Do not overtighten, as it could damage the gasket or fittings. Regularly check and retighten clamps as needed.

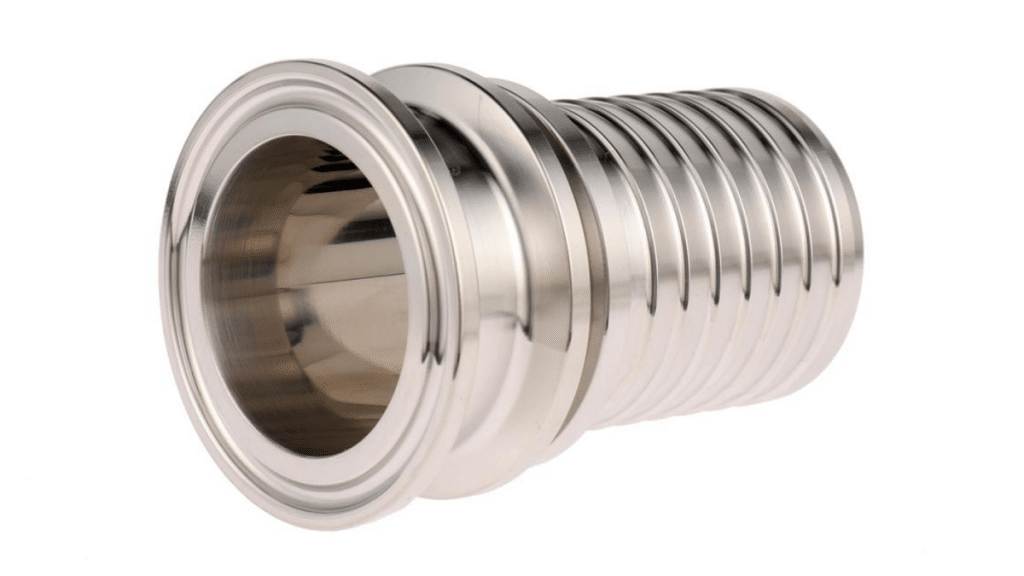

Product Highlight: Tri-Clamp Coupling by Union Metal

Union Metal is a reputable manufacturer of sanitary piping products with over 15 years of industry experience. Based in Guangzhou, China, the brand specializes in camlock fittings, couplings, rubber hoses, and more. The food-grade Tri-Clamp Coupling from the manufacturer is made from high-quality stainless steel material and meets various sanitary standards.

Key characteristics of Union Metal’s Tri-Clamps Coupling include:

- Certification: CE and ISO9001:2015

- Hygienic surfaces to prevent bacterial growth

- Compatibility with multiple fitting standards

- Versatile sizing, gasket options like silicon rubber, EPDM, etc.

- High working pressure

- Customization is available for logo, size, etc.

- Corrosion-resistant couplings. Easy to disassemble and clean

- Suitable for use in industries such as dairy, beverage, pharmaceutical, and more

Conclusion

Tri-clamp fittings are an excellent sanitary fitting choice for the food and beverage sectors, thanks to their hygienic and easy-to-clean designs. Making tri-clamp connections is easy as long as you follow proper guidelines and recommendations. For premium-grade tri-clamp products, Union Metal is a top choice with its high-quality couplings that meet international standards for performance and safety. The seasoned brand offers superior products combined with competitive pricing and reliable service, making it a trusted supplier of sanitary fixtures and fittings worldwide. Visit Union Metal’s website to browse all their offerings.