Silicone compression molding is an essential technology in the precision industry, valued for its ability to create a wide range of products with high accuracy and efficiency. Despite its importance, many people who require compression molding services may not fully understand how the compression molding process works. This article aims to fill that knowledge gap. Read on to learn what silicone compression molding is, its various applications, its numerous benefits, and more.

Definition of Silicone Compression Molding

Silicone compression molding is a manufacturing process that involves the compression of a preheated silicone rubber compound inside a mold cavity. The technique utilizes both heat and pressure to shape and cure the silicone material, resulting in the production of various components used in a wide variety of applications.

The compression molding process starts with the silicone material, being prepared and preheated to improve its flow and moldability. Following this, the silicone is positioned into the mold cavity, which is made up of two halves that close together under significant pressure. The application of heat and pressure prompts the silicone to fill the entire mold cavity, ensuring the material takes on the precise shape of the mold. This process captures even the most detailed aspects of the final product.

Applications

Silicone compression molding has many applications across various sectors. The key applications include (but not limited to) the following:

1. Medical Devices

In healthcare, where patients’ healthy and the reliability of the devices are paramount, silicone’s unique properties ensure that medical components are hypoallergenic, dimensionally accurate, and capable of withstanding harsh conditions. Whether it’s crafting intricate implantable devices or designing resilient seals and gaskets, silicone compression molding offers the versatility and reliability necessary for the medical industry to produce high-quality, life-saving devices that meet stringent regulatory standards.

2. Automotive Manufacturing

The ability of silicone compression molding to produce complex, high-precision components with consistency is essential for modern vehicles’ performance, safety, and longevity. Silicone parts crafted through compression molding provide excellent resistance to temperature extremes, chemicals, and mechanical stress, making them ideal for various automotive applications. From engine components and seals to grommets and wiring harnesses, silicone compression molding ensures the reliability, durability, and functionality of critical automotive parts, ultimately contributing to the overall performance and longevity of the vehicles you manufacture

3. Electronic Devices

Silicone’s excellent electrical insulating properties, resistance to extreme temperatures, and protection against moisture and contaminants make it an ideal material for applications such as electronic device sealing, encapsulation, and gasket. Whether it’s creating waterproof seals for smartphones, protective coatings for circuit boards, or shock-absorbing components for wearables, silicone compression molding ensures the durability and resilience of electronic devices, ultimately enhancing their usability and extending their lifespan.

Advantages of Using Silicone Compression Molding to Manufacture

Silicone compression molding offers many benefits when it comes to manufacturing. Here are some key advantages:

1. Simpler Process

The process of compression molding is relatively straightforward and doesn’t necessitate the use of complex machinery or intricate procedures. This simplicity leads to an efficient and cost-effective technique for producing components made of rubber.

2. Minimal Material Loss

The process involves minimal material waste, which makes it a cost-effective solution for manufacturing parts, especially in large volumes.

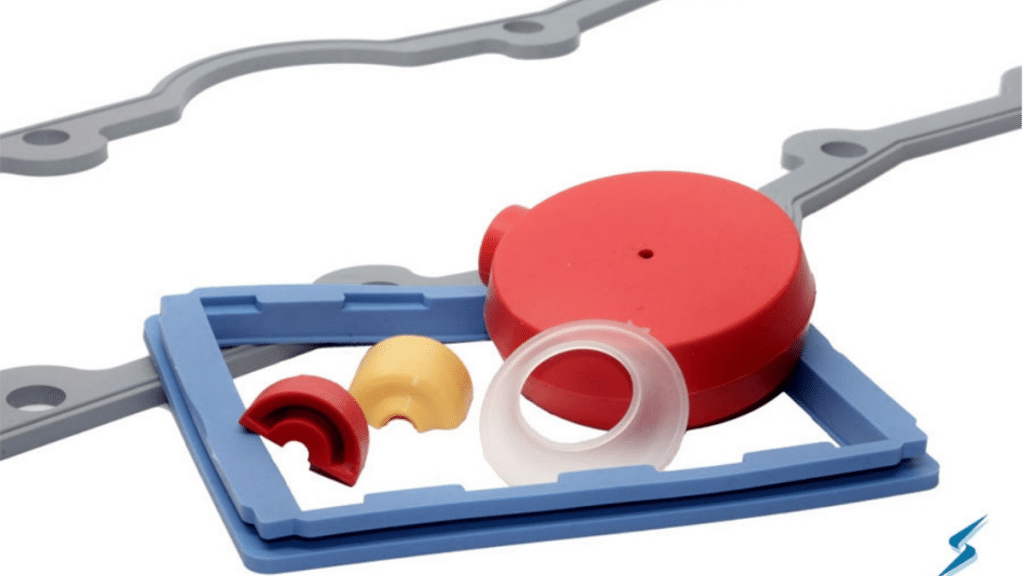

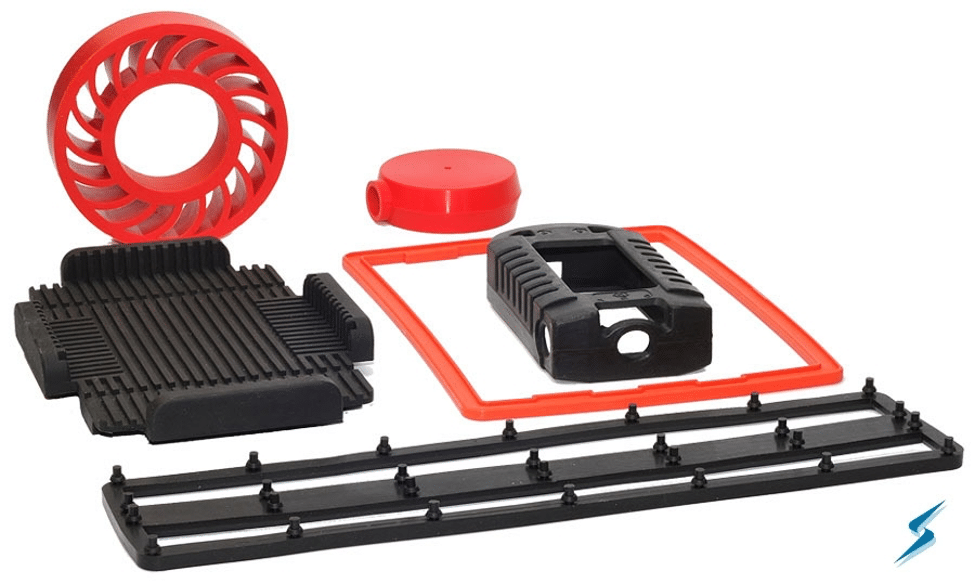

3. Color Molding

Silicone compression molding allows for the addition of pigments to the silicone, making it possible to produce parts in a variety of colors.

4. Complex Design

The process allows for the creation of parts with complex geometries and intricate details, making it a versatile manufacturing method.

5. Cost-Effective Solution

Because of its simple process and the minimal material loss, silicone compression molding can be a more cost-effective solution compared to other molding processes.

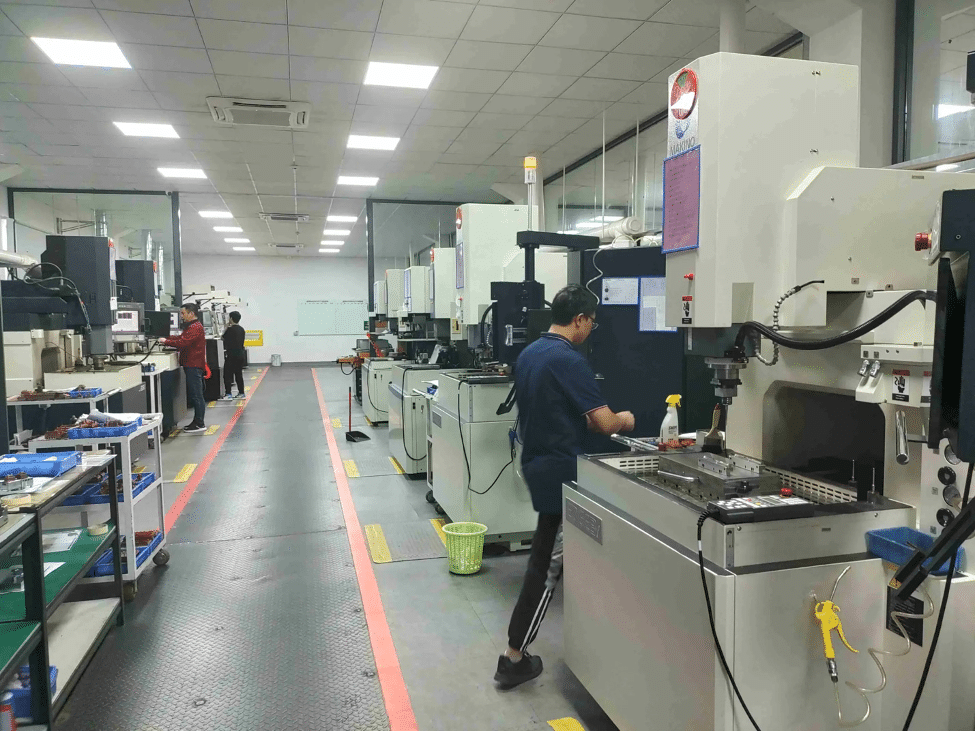

CS Mold Specializes in Silicone Compression Molding Technology

CS Mold is a seasoned provider of custom rapid manufacturing services. The brand specializes in silicone compression molding and boasts more than a decade of experience in rapid tooling services. It is well-known for providing professional services and high-quality products and solutions. Over the years, CS Mold has earned a good reputation from customers who are satisfied with its dependable services, excellent product quality, and fast lead times. Choosing CS Mold for your silicone compression molding services has several key advantages, including:

1. Quick Turnaround

CS Mold ensures that parts are made within five days, ensuring a fast and efficient production cycle.

2. DFM Analysis

Upon receiving an inquiry, the company provides a preliminary DFM (Design for Manufacturing) report. This report helps to identify potential issues before production begins, hence saving time and resources.

3. Instant Quoting

The manufacturer provides timely replies and quotes within 12 hours, helping to keep your project on schedule.

4. No Minimum Order Quantity

Unlike some other manufacturers, CS Mold does not require a minimum order quantity, making it an ideal choice for projects of any size.

5. High-Quality Products/Solutions

CS Mold is ISO 9001 and IATF 16949 certified, which means the brand follows international standards for quality management and automotive quality systems.

6. Cost-Efficient

The company is known to provide cost-efficient services, with prices significantly lower than its competitors. This makes it a more affordable solution without compromising on quality.

Conclusion

Overall, silicone compression molding is a valuable technology in the precision industry, offering a cost-effective, efficient, and versatile solution for manufacturing a wide range of products. Choosing a reliable provider of compression molding products and services is crucial to ensure the quality of your project. CS Mold, with its vast industry experience, quality assurance, and customer-centric approach, is a reliable choice for anyone looking for dependable silicone compression molding solutions. Visit the company’s website to explore all of its services and experience the benefits of its expertise in custom rapid manufacturing.