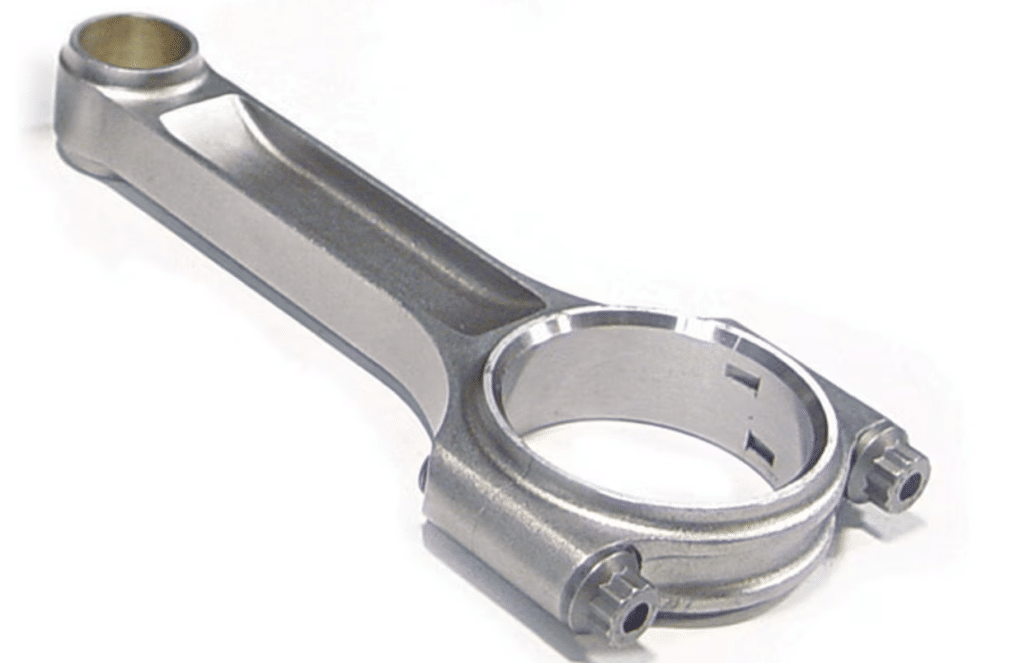

When it comes to engine performance, the components that make up the engine are critical in determining how well the engine performs under stress and high demands. One of the most crucial parts of an engine is the connecting rod. Whether you’re building a high-performance racing engine or upgrading a stock engine, understanding the differences between racing rods and stock rods is essential. This article will explore the key differences between racing connecting rods and stock ones, helping you make an informed decision for your build.

What Are Racing Connecting Rods?

Racing connecting rods are specifically designed to handle the extreme stress and demands that come with high-performance racing engines. These rods are built from materials and with construction techniques that allow them to handle much higher RPMs, horsepower, and torque than standard stock rods. Specialized rods are crafted to provide maximum strength, durability, and precision, ensuring the engine can withstand the forces generated at high speeds and extreme conditions.

In contrast, stock connecting rods are made to fit standard engine designs and typically support lower performance levels. They are sufficient for everyday driving conditions but may fail under the intense stress of high-performance racing engines. Understanding the differences in materials, construction, and applications can help you decide which rod type is right for your engine.

Materials and Construction

Racing Connecting Rods

Racing rods are often made from high-quality materials such as forged steel, billet steel, or titanium, offering superior tensile strength and durability. These materials are designed to handle extreme conditions, providing strength that ensures the rod won’t bend or break under high torque and speed. A significant advantage of racing connecting rods is that they are usually crafted from materials that can withstand high temperatures and prevent fatigue that would cause failure under regular conditions.

Here are some of the common materials used in high-performance rods:

- Forged Steel: Provides a strong balance of weight and strength, commonly used in racing applications.

- Billet Steel: Offers the highest strength and durability, perfect for high-stress environments.

- Titanium: Extremely lightweight and strong, often used for specialized applications where reducing weight is critical.

- Aluminum: A lighter alternative, used in high-performance applications where lightweight components are a priority.

The racing connecting rod market has a variety of options based on performance requirements. For example, forged steel rods are one of the most popular choices, as they provide an excellent balance of weight and strength. Other materials, such as aluminum or titanium, are used for specialized applications that require lightweight performance parts with strength characteristics that can handle high RPMs.

Stock Rods

Stock connecting rods, on the other hand, are typically made from less durable materials like cast iron or lighter-duty steel alloys. While these materials are sufficient for standard engine applications, they cannot handle the extreme stress placed on the engine by high-performance driving or racing conditions. Stock rods are designed for reliability under normal conditions. They aren’t built to support high horsepower, high torque, or high RPMs over prolonged periods.

Here are some materials commonly found in stock rods:

- Cast Iron: A cost-effective material, used in standard engine builds but lacks the strength for high-performance applications.

- Mild Steel: A basic material choice that works well for standard applications but won’t handle the extremes of racing conditions.

For a stock engine, these rods work well within the manufacturer’s recommended operating conditions. However, once you begin pushing the engine beyond those limits, the stock rods will likely fail, as they are not built for high-performance stress. This is where racing connecting rods become essential.

Performance and Durability Differences

The Strength of Racing Rods

When you’re building an engine for high-performance applications, the strength and durability of your components become paramount. Racing connecting rods are designed to withstand the rigors of extreme horsepower and RPM. These rods are not just about being stronger; they are also about being more resilient. They can handle significantly higher loads and are resistant to the wear and tear that would normally cause failure in standard rods.

For example, racing engines often operate at RPMs that exceed 10,000, which puts an immense amount of stress on the rods. Racing rods are engineered with precise geometries, high-strength materials, and advanced forging processes to ensure that they stay intact under these conditions. This added durability ensures that racing engines can run at high RPMs for extended periods without fear of connecting rod failure, which is crucial in competitive motorsports where every second counts.

Limited Performance Capabilities of Stock Rods

Stock rods, however, are typically only designed to handle the power output of a regular engine under normal driving conditions. These rods are sufficient for daily commuting or light-duty applications. While stock rods can handle typical engine speeds (up to around 6,000 RPM), they begin to experience fatigue and failure once subjected to sustained high RPMs, higher horsepower, or extreme driving conditions.

This limitation in strength and performance makes stock rods unsuitable for racing applications, where engine performance is pushed to its limits. If you plan to push your engine to its performance boundaries, racing connecting rods are an essential upgrade.

Cost and Applications

Upgrading to Racing Connecting Rods for Peak Performance

One of the major differences between racing and stock rods is the cost. Racing rods are typically more expensive due to the higher-quality materials and manufacturing processes. For example, titanium or billet steel rods require advanced forging techniques and specialized equipment, making them more costly to produce.

While the cost of a racing connecting rod may be higher, it is an investment in your engine’s performance and durability. Whether you’re building a competitive racing car or a performance engine, the durability and strength of specialized rods will give you the confidence to push your engine to its limits without the fear of failure.

Keeping Budget-Friendly Stock Rods

Stock connecting rods are much more affordable due to their simpler manufacturing processes. These rods are mass-produced to fit a wide range of standard engine designs. While they are a cost-effective solution for everyday driving, they lack the strength and durability necessary for high-performance applications.

If you’re building an engine for daily driving or general use, stock rods may be sufficient. However, if you’re aiming for serious performance upgrades or building a race-ready engine, investing in racing connecting rods is essential for power and reliability.

To Sum Up

In summary, the decision between racing and stock rods depends on the performance you require from your engine. While stock rods are designed for everyday driving and can handle lower horsepower and RPMs, racing connecting rods are engineered for high-performance applications, where durability, strength, and resistance to high stress are critical.

If you’re building an engine for racing or high-performance use, investing in specialized connecting rods is essential to ensure that your engine can withstand extreme conditions and deliver peak performance. While racing rods come at a higher cost, the benefits in terms of strength, durability, and engine reliability make them worth the investment for serious enthusiasts and professional racers alike.