Packaging can be made beautiful with a few specific things that can’t be ignored in any case. Vape cartridges are the hottest products in the vape industry, and they must be present in complete packaging boxes by a leading firm. For this purpose, you must review and research the professionals near you. One of the important options to make your packaging cases alluring is digital printing and offset printing. Now the question is what to select and which one is better according to your need.

Many times, especially if you are new to printing & packaging, you await a certain color or quality to be generated exactly what is expected on the screen. The reality is that printing results cannot completely match what we sight on the monitor based on the RGB vs. CMYK shade result theory.

Yes, the result’s quality can be calibrated to imitate closely to what it should look like, but it will depend on the method and techniques used. That is where many company’s owners, designers, and marketers run into a hurdle when experiencing their first packaging project.

In this content, you will understand how to effectively pick the correct type of print for your packaging and understand the differences in results based on artwork objective, charges, and options. You can get the special packaging boxes of THC cartridge Stampa Prints. In detail, let’s discuss the better selection; after all, it’s about your product’s security and presentation.

Digital vs. Offset Print

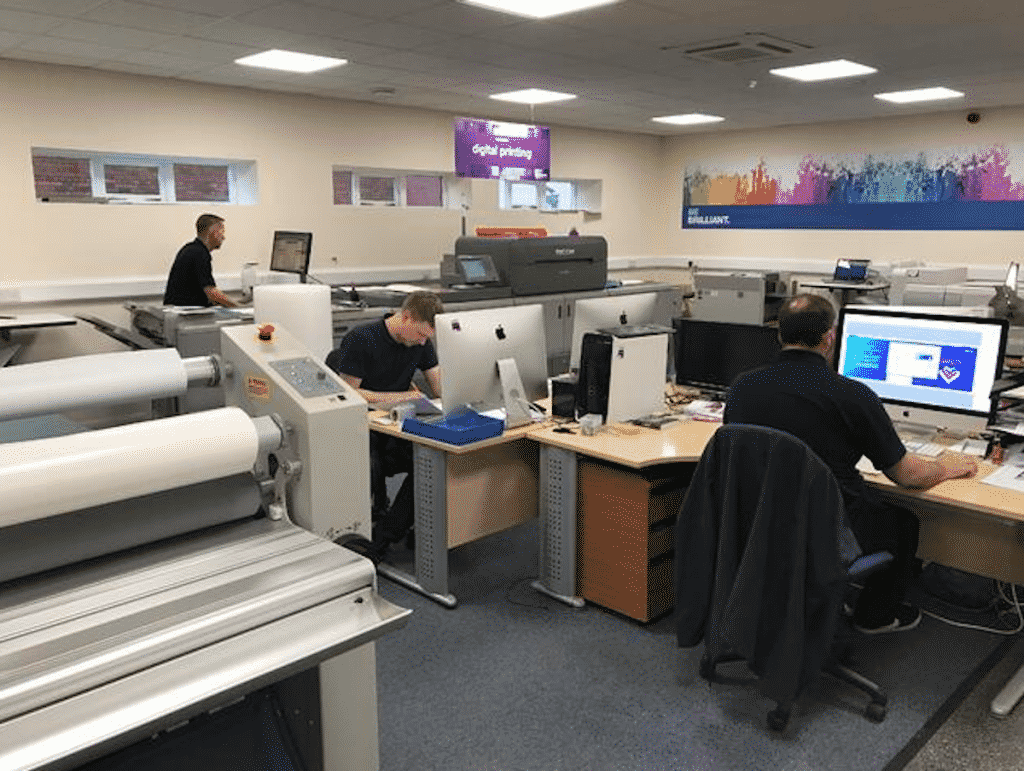

The two key printing ways you can use for your packaging are offset lithographic printing or digital printing; few people may not know about the difference so read it carefully.

Offset Print

Offset print uses metal plates coating color onto sheets in speedy succession. That is how newspapers and magazines are generally developed. It provides superior image quality and worthwhile for large-volume print runs but is too costly for most low-level projects and takes extra time to finish.

Digital Print

Digital print, on the other side, is how your home office laser or inkjet printer functions. It provides immediate turnaround times and makes low-volume jobs reasonable. It’s also simpler to develop variable data print runs using a digital printing press.

Although, digital printers can’t quite match the color allegiance and material flexibility that offset printing provides. According to Smithers Pira, digital printing results in 16.4 percent of global print and packaging in terms of worth, but only 3.9 percent of the print industry’s volume. That appears to fortify the idea that digital printing is the best low-volume print option. But there is further to the question than just differentiating print volume.

So, What Do You Pick?

Material

Rigid packaging mainly needs offset printing. If you’re going to print on luxury packaging cases, you might as well print in an offset to get the top quality possible.

Corrugated packaging can help you from either digital or offset. Offset is advantageous for designs that need an additional process such as spot UV and foil stamping and requires a volume of over 1000 units.

For smaller runs and easier designs for e-commerce packaging boxes, digital is the technique to go. Paperboard packaging mainly needs offset, particularly for cosmetic, pharmaceutical, and small retail packaging cases.

Why? Offset serves a clearer and more vivid printing result for smaller messages and designs.

Turnaround Time

For temporary runs in corrugated, digital is the perfect option with regard to turnaround time and offset for the long run. The offset can generally print instantly in greater volume.

Quality Color Depth

However, offset printing can be more costly; it does outshine digital printing when it comes to shininess and color immensity.

Offset printers have the tendency to use the Pantone Matching Color System to outstandingly match inks, whereas digital printers can only approximate these shades using color calibration. The offset can also print white ink on specific kraft paper while digital cannot.

Offset generates the clean, crisp, alluring color results that you see in retail stores, while digital generates fine quality for simpler designs (well-suited for e-commerce packaging).

Types of Coating

Offset printing also permits a huge coating range, including matte & gloss laminate, UV, soft touch, and AQ coating, while digital cannot.

Prototyping

These two printing techniques can aggregate one another in most packaging orders.

It is simpler and more cost-friendly, for example, to use digital printing to develop packaging prototypes and then put the final packaging items through full manufacturing-grade offset printing (although this may result in slight alteration in color during total production).

It is suggested to request a physical CTP proof to confirm printing instead. Prototyping in offset is attainable but needs more time and cost.

Quantity

For folding cartons and rigid packaging boxes, no matter what quantity, offset is favored. If you are generating corrugated, any orders lower than 500 pieces should think about digital for cost-effective choice and offset amounts larger than 1000-2000 pieces due to the fine quality of printing.