In today’s world, electronic and industrial devices are getting more powerful and compact. This means heat dissipation has become a crucial aspect. Effective heat dissipation ensures devices run smoothly and last longer. In this article, we’ll explore different types of heat dissipation components and their characteristics. We’ll pay special attention to Peltier coolers, a fascinating technology with unique advantages.

The Importance of Heat Dissipation

Heat dissipation plays a key role in device performance. When a device overheats, it can slow down or even stop working. Efficient heat dissipation helps maintain optimal performance. It also extends the lifespan of the device. Overheating can cause components to degrade faster, leading to frequent repairs or replacements.

Overheating can be caused by various factors, including high power consumption, inadequate ventilation, and environmental conditions. The consequences of overheating are serious. They include reduced performance, unexpected shutdowns, and permanent damage to the device. Effective heat dissipation prevents these issues.

Thermal management is vital in both the design and maintenance of electronic devices. During design, engineers must consider how to dissipate heat efficiently. Maintenance involves regular checks and upgrades to ensure the cooling system is working well. Proper thermal management keeps devices running efficiently and extends their useful life.

Types of Heat Dissipation Components

Effective heat dissipation is essential for maximizing the performance and longevity of electronic devices. Traditional cooling methods include fans, heat sinks, and heat pipes. These methods are widely used and have proven to be effective.

1. Fans

Fans are the most common cooling method. They work by moving air across a heat source, carrying away the heat. Fans are inexpensive and easy to install, but they can be noisy and consume power.

2. Heat Sinks

Heat sinks absorb heat from the device and dissipate it into the surrounding air. They are made of materials with high thermal conductivity, like aluminum or copper. Heat sinks are silent and passive, meaning they don’t need power to work. However, they might not be sufficient for very high-power devices on their own.

3. Heat Pipes

Heat pipes transfer heat from a hot area to a cooler one using a liquid-vapor phase change. They are very efficient and can move heat over long distances. Heat pipes are more complex and expensive than fans and heat sinks but offer superior performance.

Peltier Coolers: Thermoelectric Cooling Technology

Peltier coolers use thermoelectric technology to transfer heat. They have some unique advantages and applications.

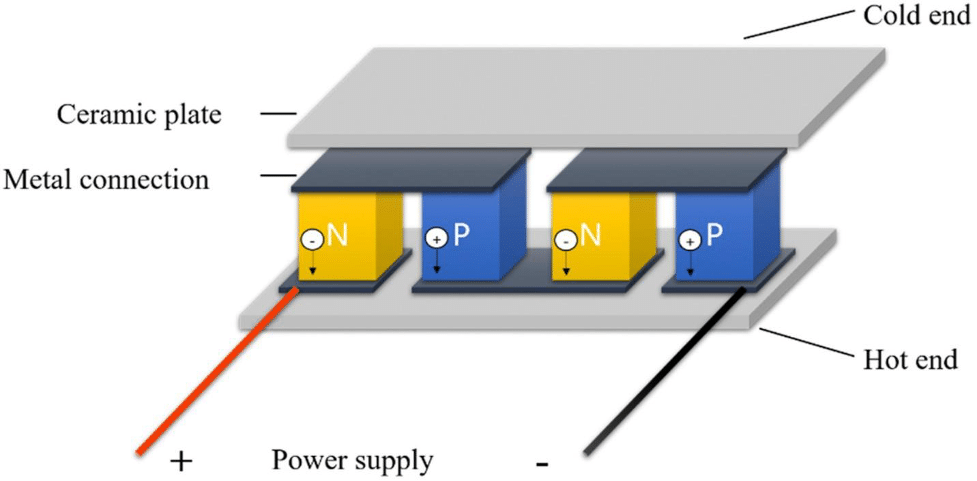

Peltier coolers, also known as thermoelectric coolers, work on the principle of the Peltier effect. When an electric current passes through two different conductors, heat is absorbed at one junction and released at another. This allows one side of the cooler to become cold while the other side gets hot. Peltier coolers are compact and have no moving parts, making them reliable and quiet.

Comparison with Other Cooling Methods

Compared to traditional methods, Peltier coolers offer precise temperature control. They can cool below ambient temperature, which is not possible with fans or heat sinks alone. However, Peltier coolers are less energy-efficient and can generate significant heat on the hot side, which needs to be managed.

Applications

Peltier coolers are used in various applications, including cooling electronic components, small refrigerators, and even in scientific instruments. Below are some specific application scenarios:

● Medical: Peltier coolers are used in medical devices that require precise temperature control, such as diagnostic equipment and portable vaccine storage units.

● Beauty: In beauty devices, such as laser hair removal systems and skin treatment tools, Peltier coolers help maintain optimal operating temperatures for safety and effectiveness.

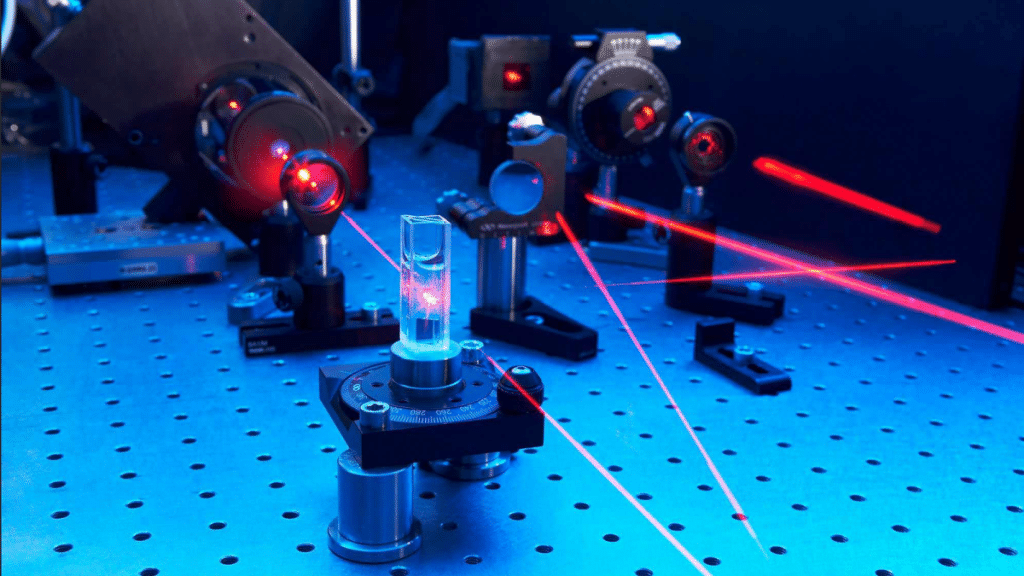

● Laser: High-power laser systems use Peltier coolers to manage the significant heat generated during operation, ensuring stability and longevity.

● Telecom: In telecom equipment, Peltier coolers help keep sensitive components cool, ensuring reliable performance and extending the lifespan of devices like base stations and signal processors.

● New Energy Automobile: In car refrigerators, Peltier coolers are used to maintain consistent low temperatures, ensuring the freshness of food and beverages, providing convenience and comfort for travelers.

● Unmanned Aerial Vehicle (UAV): Drone charging boxes utilize Peltier coolers to prevent overheating of critical components, ensuring stable flight times and operational efficiency.

● Consumer Electronics: Devices like laptops, gaming consoles, and cameras benefit from Peltier coolers to manage heat, improving performance and user comfort.

Cooling Methods of Peltier Coolers

Effective cooling methods are crucial for managing heat in electronic and industrial applications. Peltier coolers offer versatile solutions through various cooling methods:

1. Direct Cooling (Plate to Plate)

In direct cooling, the Peltier cooler is in direct contact with the heat source. This method is simple and effective for small areas. It provides efficient cooling but requires careful management of the heat generated on the hot side.

2. Plate to Air

This method combines cold plates with air heat exchangers. The cold plate absorbs heat from the device, and the air heat exchanger dissipates the heat into the surrounding air. It’s effective for moderate power levels and allows for flexible design.

3. Plate to Liquid

In plate-to-liquid cooling, the cold plate is combined with a liquid circulation system. The liquid absorbs heat from the cold plate and carries it away to a radiator or heat exchanger. This method is very efficient and suitable for high-power applications but requires a more complex setup.

4. Liquid to Air

This method uses liquid heat exchangers combined with Peltier modules. The liquid absorbs heat from the device and transfers it to the air via a heat exchanger. It offers high efficiency and is suitable for high-power applications with significant heat loads.

5. Air to Air

In air-to-air cooling, both sides of the Peltier cooler are exposed to air. This method is less common but can be used in applications where both the hot and cold sides need to be managed through air circulation.

6. Liquid to Liquid

This method involves transferring heat from one liquid to another using Peltier modules. It’s highly efficient and can be used in specialized applications requiring precise temperature control.

Huajing’s Heat Dissipation Solutions

Huajing is a leader in the field of thermoelectric cooling solutions. They prioritize customer satisfaction and adhere strictly to product quality standards. Their products are known for:

● High Temperature Control Accuracy: Their thermoelectric cooler assemblies ensure precise temperature control, crucial for sensitive applications in industries ranging from medical to telecommunications.

● Fast Response Speed: Leveraging semiconductor technology, their coolers respond swiftly to temperature changes, facilitating rapid adjustments without delays.

● Low Noise Operation: Designed for silent operation, their assemblies operate quietly, making them ideal for environments where noise is a concern.

● Easy Maintenance and Control: They emphasize user-friendly designs that are easy to maintain and operate, reducing downtime and enhancing reliability.

● Compact and Lightweight: Their products are compact and lightweight, suitable for space-constrained applications in various industries.

● Long Lifespan and High Reliability: With a commitment to quality and continuous improvement, Huajing’s thermoelectric cooler assemblies offer long-term reliability even under demanding conditions.

Conclusion

Heat dissipation is critical for the performance and lifespan of electronic devices. Traditional cooling methods like fans, heat sinks, and heat pipes are effective for many applications. Peltier coolers offer unique advantages, including precise temperature control and the ability to cool below ambient temperatures. However, they require careful management of the heat they generate. By understanding the different types of heat dissipation components and their characteristics, you can choose the best solution for your needs. Peltier coolers, with their versatility and efficiency, are a valuable option in modern thermal management.