Product integrity and shelf appeal dominate the cosmetics industry, and efficient and quality packaging is vital. Consequently, horizontal cartoners are essential. These machines handle delicate items for consistent, damage-free packaging at high speeds. Moreover, their versatility accommodates numerous cosmetic product sizes and types. It helps optimize packaging line efficiency and uphold product aesthetics for consumer attraction and brand reputation.

Types of Horizontal Cartoners in the Cosmetics Industry

Let’s illustrate the different types of horizontal cartoning machines in the cosmetics industry.

1. Continuous Motion Horizontal Cartoner

Continuous motion horizontal cartoners are needed for high-speed packaging in the cosmetics industry. Their continuous conveyor systems move at a constant speed, enabling the products to be packed without interruptions. This mechanism benefits products like lipsticks with required consistency in orientation and gentle handling. Furthermore, their design may include servo-driven loaders and quick-change size parts for rapid changeovers and curtailed interruption.

2. Intermittent Motion Horizontal Cartoner

Intermittent motion ones are tailor-made for lower-speed operations with needed flexibility and precision. They stop and start at specific points when packaging, which enables much more gentle and accurate control and positioning, making them handy for delicate or irregularly shaped cosmetics. These cartoners may combine vision systems for precise product placement and reject mechanisms for quality control.

Considerations for Choosing Horizontal Cartoners

Here are the typical considerations for choosing horizontal cartoning machines for the cosmetics industry.

1. Adaptability to Product Sizes and Shapes

In cosmetics, horizontal cartoning machines must house product sizes and shapes, from compact lipstick tubes to large lotion bottles. It needs a flexible machine design with adjustable parts or modular setups. E.g., a cartoner with an adaptable conveyor system and changeable product pockets can handle numerous product dimensions without negotiating stability or alignment during packaging.

2. Gentle Product Handling

Given the delicate nature of many cosmetic products, gentle handling is vital. Horizontal cartoning machines in this sector should come with conveyor systems and loading mechanisms that can handle items carefully. It helps prevent damage, scratches, or deformities during the process. For instance, they may employ soft-touch mechanisms and controlled-motion conveyance to lessen impact and vibration.

3. High-Speed Operation and Throughput

Efficiency is key in high-demand markets. A handy horizontal cartoner for cosmetics should offer high-speed operation with precision. Radical synchronization technology and rapid yet stable mechanical movements may attain this. For example, a cartoner processing 100 units per minute with constant accuracy is sought after, which provides a balance between speed and reliability.

4. Compliance with Regulatory Standards

Compliance with industry-specific standards, including Good Manufacturing Practices (GMP), is firm. Horizontal cartoning machines must meet hygiene and safety regulations while featuring easy-to-clean surfaces and materials resistant to cosmetic chemicals. Further, integration capabilities with track-and-trace systems help meet regulatory requirements for product traceability and authentication.

5. User-Friendly Interface and Maintenance

Ease of operation and maintenance impacts productivity. Cartoning machines for cosmetics should boast intuitive user interfaces for quick setup and troubleshooting. Likewise, machines with modular and easily accessible parts simplify upkeep. E.g., a cartoner with a touchscreen control panel for real-time diagnostics and alerts results in smoother and more efficient operation.

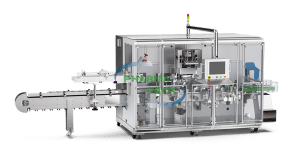

Trusted Pick: Pharmapack’s LFBI-10 Intermittent Horizontal Cartoner

Being a leading enterprise in the smart packaging industry, Pharmapack is acknowledged by famous brands from the pharmaceutical, food, and cosmetics industries. Specifically in the cosmetics and personal care industry, it has established potent partnerships with P&G, L’Oreal, Blue Moon, and more. Next, let’s have a glimpse of it through one of its competitive products, the LFBI-10 Intermittent Horizontal Cartoner.

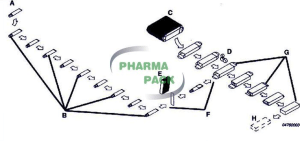

For basic information, it handles many box sizes (115~200 mm x 40~130 mm x 15~80 mm), operates at a maximum speed of 100 pieces per minute, and complies with leaflet sizes up to 300 mm x 200 mm.

Its “Balcony” structure boosts accessibility for care and cleaning with GMP compliance. Notably, the scratch-resistant white-toothed conveyor chain guarantees the uprightness of smooth cartons for fragile products.

The machine’s PLC controller and liquid crystal touch interface simplify operation and product changeovers. Undoubtedly, it exemplifies productivity and flexibility in high-standard packaging environments.

Conclusion

Established in 2002, Pharmapack develops, manufactures, and integrates smart packaging solutions. With attention to novelty and quality, the company offers many solutions, including intelligent bottle packaging lines, automatic inspection packaging lines, and secondary packaging line equipment. Their horizontal cartoner solutions typify their words to unconventional and efficient packaging solutions.

What’s more, Pharmapack’s global presence in Italy and beyond combines international expertise for better technical support and services. Choose Pharmapack, and get ready to see how their expertise helps you thrive regarding the packaging process.