The applications of hermetic packaging enjoy a wide spread influence, since delicate devices must be maintained in a quality environment to ensure their capabilities. That is where hermetic packaging comes into play.

For example, the launching of a communication satellite into low orbit relies on the leverage of all components, meaning that even the tiniest breach in that packaging could turn a multi-million-dollar project into relative space junk. The key is understanding what type of electronic packaging will work best for your product, and Hermetix is here to help.

What Types of Hermetic Packaging are Available?

Electronic packaging serves as a safeguard for delicate electronic and microelectronic components. It acts as a usable shield, defending parts from unwanted and unpredictable environmental factors like moisture, chemicals, and physical impact.

The efficacy of this hermetically sealed packaging varies across different types that may include:

- Non-Hermetic Packaging: This is the least secure form of packaging you’ll find with most products. It generally employs polymeric materials and coatings like PEEK (Polyetheretherketone) and Parylene-C.

- Near-Hermetic Packaging: A step up in reliability, near-hermetic options use materials like Liquid Crystal Polymer (LCP) and offer a better but not absolute barrier against environmental risk outside of more reliable items like glasses, metal, or ceramics.

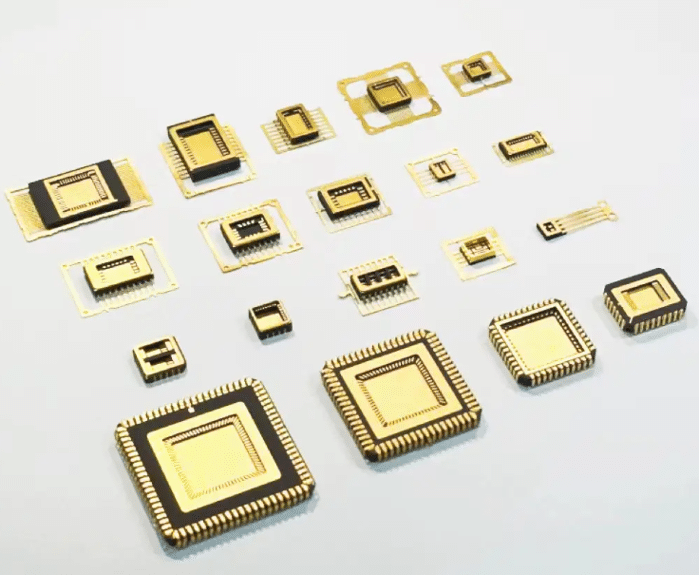

- Hermetic Packaging: This is the gold standard of packaging for various microelectronics. It often utilizes glass, metals, and ceramics to provide an almost impermeable shield for electronic components from the dangers of liquids, dust, and other materials that could compromise the element in question.

Each electronic packaging type offers its pros and cons, which leads us to the question—What truly differentiates them?

Defining Hermeticity and Exploring Differences

Hermeticity is a broad term that refers to the absolute sealing of an object within some form of packaging. This is typically intended to make the object impermeable to external factors like gas and moisture. While hermetic packaging achieves this standard, near-hermetic and non-hermetic packaging don’t—but to varying degrees.

1. Material Differences

Most hermetic packing uses robust materials through inert glass, metals, or ceramics. This is the highest level of protection against external variables that can cause the internal item to degrade or malfunction. Not all electronics need that level of security. Instead, you can leverage near-hermetic and non-hermetic pacing that uses polymeric materials such as LCP and PEEk – offering good, but not 100%, absolute projection against various environmental factors.

2. Performance Difference

If you are in the business of mission-critical applications like aerospace, microchipping, or other crucial microelectronics, complete hermetic packaging is the best choice. That will give you far more long-term reliability through reliable packaging. Both near and non-hermetic packaging offer somewhat decent protection but will degrade over time and tend to be used in consumer electronics situations where maximum reliability is not such a factor.

3. Application Difference

You will see hermetic packaging in MIL-compliant and high-reliability projects that involve space, deep sea, or medical uses. These are the applications where failure is not an option due to the sensitive nature of the situation. The other two possibilities all depend on the unique need of the product but tend to be way less crucial to operational success. This is due to the less critical industrial application that balances cost and performance in favor of profit maximization.

Why Choose Hermetix for Your Hermetic Packaging Needs?

Hermetix is a leading name in the metal packaging industry. This reliable provider offers an extensive range of hermetic packages, from MIL-compliant series to conventional civilian-standard series.

Hermetix products offer a varied use-case selection, including optoelectronic packaging, ceramic packages, glass to metal hermetic seals, and other hermetically sealed packaging solutions. This team of experienced and recognized quality engineers ensures that every product meets the high-performance, high-reliability requirements crucial to hermetic packaging.

Wrapping Up

When you consider which primary electronic packaging to choose from (non-hermetic, near-hermetic, and hermetic), it all boils down to your project’s application, performance requirements, and budget.

When the stakes are high, hermetic packaging emerges as the unequivocal choice for ensuring the longevity and reliability of your electronic components.

For those who value reliability and performance, the answer is clear with Hermetix. Contact the company today or view the various products available to ensure your microelectronics and other sensitive components’ safety, integrity, and durability.