Welcome to the dynamic world of 3D printing, where creativity meets technology, and endless possibilities are right at your fingertips. Like any valuable tool, however, a 3D printer requires regular maintenance to ensure optimum performance and a consistent output of high-quality prints. This article is your comprehensive guide to maintaining your 3D printer, covering the essential steps from regular cleaning to troubleshooting common issues.

Understanding Your 3D Printer

First and foremost, understanding the different components of your 3D printer is crucial to effective maintenance. A typical 3D printer consists of the build platform, extruder, and filament, along with various smaller parts. A well-maintained printer provides accurate prints, operates quietly, and boasts an extended lifespan.

Regular Cleaning

Over time, debris can accumulate in different parts of your 3D printer, affecting its performance. Regular cleaning is thus essential.

1. Build Plate:

This is where the actual printing occurs. Ensure to remove any remnants of filament after each print job. A spatula is a handy tool for this job, but be cautious not to scratch the build plate.

2. Extruder:

Cleaning the extruder prevents it from clogging, which can cause substandard prints. Use a fine brush to clean off any accumulated dust or filament particles.

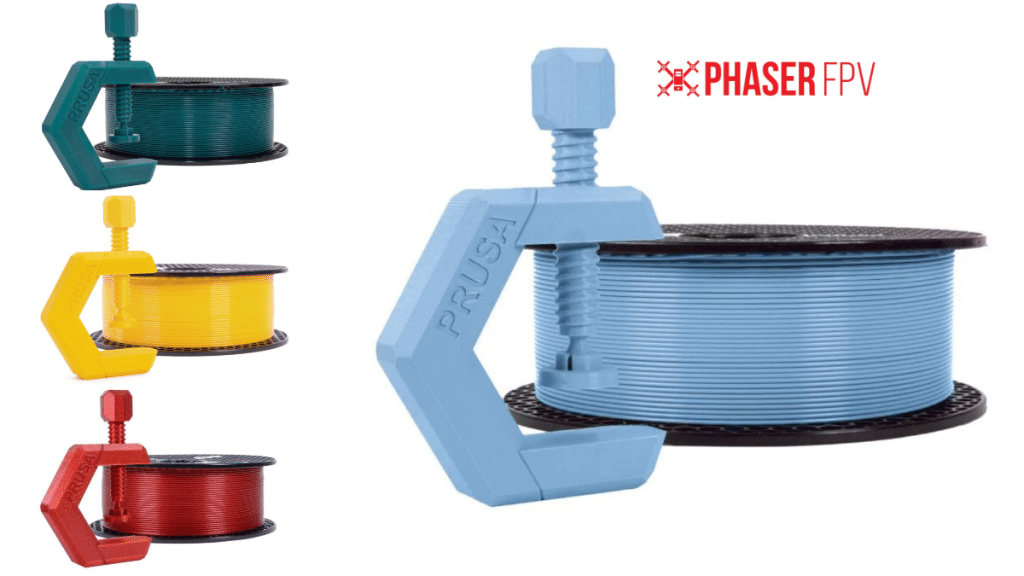

3. Filament:

Always store filament in a clean, dry place to prevent contamination. If left exposed, it can absorb moisture, causing prints to become brittle and break easily.

Lubrication

Moving parts like the rods and bearings require lubrication to operate smoothly. This reduces friction, limiting wear and tear. Use a light machine oil, applying sparingly but regularly. Always check your manufacturer’s recommendations for the best results.

Firmware Updates

Manufacturers often release firmware updates to enhance printer performance or fix known issues. It’s vital to regularly check for these updates and install them when available. The process typically involves connecting your printer to a computer via USB and following the manufacturer’s instructions.

Calibration

Over time, parts of your 3D printer can become misaligned, affecting the quality of your prints. Regular calibration can ensure that all parts work in harmony. Key areas to check include the build plate level, the extruder’s alignment, and the belt tension.

Replacing Parts

Despite your best maintenance efforts, some parts will naturally wear out over time and will need to be replaced. A common example is the printer’s nozzle, which can become worn or blocked over time, affecting the print quality.

When it’s time to replace or upgrade parts, 3D printer accessories and parts can be easily sourced – from nozzles to drive gears, you’ll find what you need to keep your 3D printer in top shape.

Regular maintenance is the key to ensuring your 3D printer’s optimum performance and longevity

By taking the time to clean, lubricate, calibrate, and replace worn parts when necessary, you can enjoy consistent high-quality prints and a machine that serves you well for many years. With the right care and attention, your 3D printer can remain a reliable tool in your arsenal of creativity and innovation.