During a time of global economic and health uncertainties, packaged products are a necessity. Whether it’s pharmaceuticals, medical testing kits, or food products, the packaging is essential to keep the contents safe and healthy. Hardly any pharmaceutical, food, and healthcare industries can carry on production without packaging, which is a key process to entering the market. And that’s why the automatic carton filling machine enters the market.

To assist an informed decision about the automatic carton filling machine, this article tailored a guideline about the automatic carton filling machine. Please scroll down to learn more about automatic carton filling machines.

What Is the Automatic Carton Filling Machine?

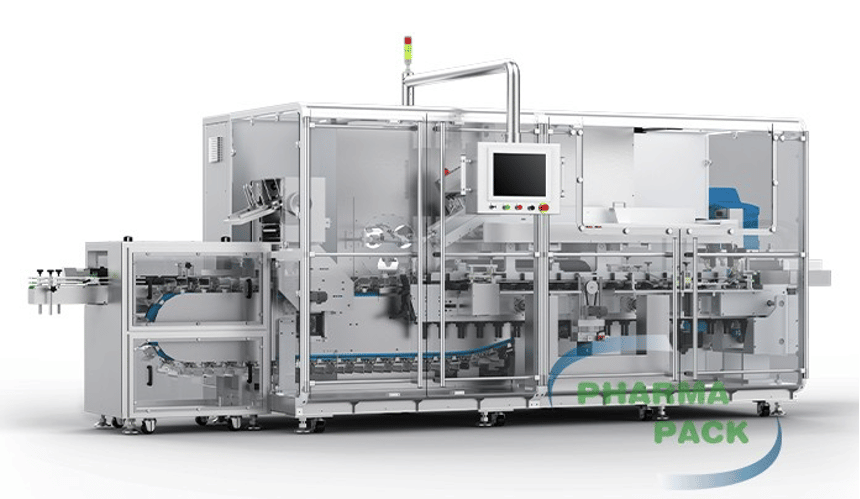

The automatic carton filling machine, named as filling and sealing machine, is a piece of mechanical equipment that completes the packing of various commodities under the packing request set in advance. For instance, the machine automatically loads medicine bottles, boards, ointments, and other materials into cartons to facilitate product transportation and increase the aesthetic appearance of products. With the continuous changes in market needs, automatic carton filling machine brings higher power to the company’s production.

In addition, it is the foundation of the complete packaging line and a must for packaging in the modern pharmaceutical industry. By virtue of excellent performance, the automatic carton filling machine has become the best choice for many companies in packing work.

Common Types of Automatic Carton Filling Machines

In light of the position where the carton is fed, the automatic carton filling machine can be divided into vertical and horizontal form fill seal machines. From another perspective, it can be divided into continuous and intermittent types according to the operational mode.

1. Continuous Cartoner

An automatic continuous cartoner can be identified as a high-speed packing machine applied to a high-speed production line. Primarily, it is designed for regular shaped and solid products that require few special handling provisions, which means the continuous model is suitable for small packaging products with a fast packaging speed. As a result, this automatic carton filling machine model increases production speed, achieving a much higher production capacity.

2. Intermittent Cartoner

The intermittent cartoner is similar to the continuous model. The major difference comes is speed, as the intermittent mode automatic packing is slower. For instance, the intermittent cartoner is a linear reciprocating movement with stopping and giving time for the packaging cycle. In this condition, the machine is limited by the intermittent movement of the transmission mechanism, making the production speed much lower.

Application Areas of Automatic Carton Filling Machine

As aforementioned, the automatic carton filling machine enables progressive and perfect insertion of the products. The filling and sealing machine is very useful in different industries as it allows the filling and packaging of the product to be more cost-effective. In addition, it is frequently used in pharmaceuticals, cosmetics, food, and many others to enhance packaging speed and lower operating costs.

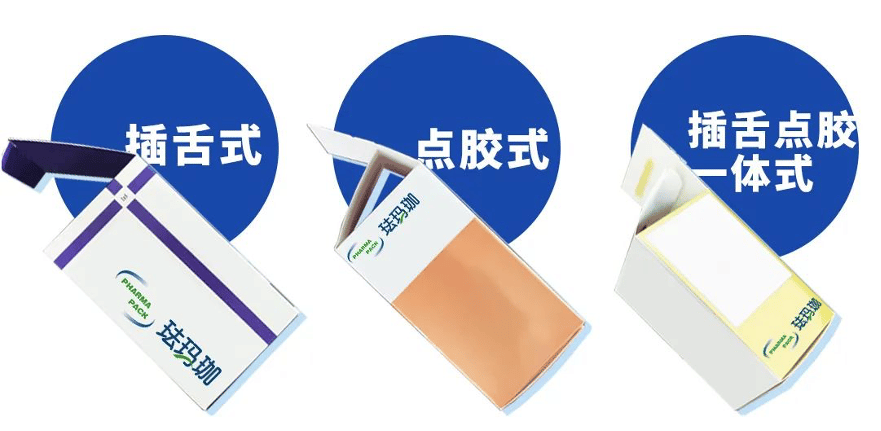

Main Sealing Forms of Automatic Carton Filling Machines

After getting some basic knowledge of automatic carton filling machines, let’s dive into their main sealing forms when packaging.

From left to right:

truck-in, dispensing, and integration of truck-in and dispensing closure

1. Tuck-in Closure

The tuck-in closure uses the flaps of the carton in order to create a lasting closing technique. The flap, which can also be referred to as the tongue, which can stick with shore locks or friction fit.

2. Dispensing Closure

This innovative technique involves the application of hot glue onto the flaps in order to create a permanent seal on the cartons. This closure is designed for cartons that may carry heavier products, especially at the bottom.

3. Integration of Dispensing and Tuck-in Closure

Some cartons have a combination of dispensing and tuck-in closures to improve the strength of the carton. People may find a carton with dispensing closure on the sides at the bottom or of the carton. The tuck-in closure is often at the top, making it much easier for users to open and close the carton.

Merits of Automatic Carton Filling Machines

With the improvement of science and technology, the automatic carton filling machine industry has greatly improved in terms of technical level and equipment functions. In addition, it has played an important role in supporting enterprises’ production efficiency with the following merits:

1. Automation

With high automation, the automatic carton filling machine uses a high-speed distribution device to pack various containers, bottles, cans, boxes, and other materials. For instance, the clip picked the items up and placed them in the opened carton. When the grab head is raised, the carton is discharged and sent to the sealing machine, which PLC and touch screen can control.

The assembly line is easy to operate and manage, reducing production personnel and labor intensity. Moreover, the automatic carton filling machine is the best assistant if you have a huge production need since it can package target items wonderfully and automatically in bulk.

2. Non-Pollution

Using automatic carton filling machines can avoid secondary pollution of products and improve product quality. Misconduct in the manual packing process can easily cause damage to the appearance of the box or the internal medicine. Therefore, automatic carton filling machines can improve the quality and prevent the carton from being damaged by avoiding pollution in the packing process with the fixed packing procedure.

3. High Efficiency

The use of automatic carton filling machines can improve efficiency. For instance, these machines can eliminate the inertia of manual operation. It is because people working for a long time will produce a sense of inertia and fatigue and will extend the time of opening and closing the mold when it is taken out. Using manipulators can eliminate the inertia and fatigue of manual operation, and there is no need to worry about the absence of workers.

Final Words

Since the market offers a number of automatic carton filling machines, it is a daunting task for most people to decide which cartoner could be their ultimate choice. This article undertakes this initiative to assist you in reaching a trustworthy packing machine manufacturer.

Pharmapack specializes in cost-effective equipment and its integration for the pharmaceutical, food, and healthcare industries. Additionally, by fully integrating European manufacturing processes and advanced technologies, Pharmapack provides customers with the most advanced and guaranteed technical support. Now it is time to stop folding cartons by hand and cooperate with the Pharmapack. Get more useful information about Pharmapack now.