A vacuum pump is a device that creates a low-pressure or vacuum state by extracting gas. It has a wide range of applications in various industries, such as manufacturing, scientific research, chemistry, and food processing.

One of the key components that help vacuum pumps function efficiently are rotor vanes, which play a major role in extracting gas and regulating gas changes in the vacuum pump. Graphite rotor vanes are particularly popular due to their characteristics, like corrosion resistance and good thermal conductivity, which make them suitable for vacuum pumps.

Characteristics of Graphite Rotor Vanes

Graphite rotor vanes are widely used due to their several inherent qualities. It’s not surprising that they are the material of choice for many industrial vacuum pumps. Their key characteristics include:

- High-Temperature Resistance

Graphite has a high melting point of 3650°C, making graphite rotor vanes resistant to temperatures far exceeding the operational limits of vacuum pumps.[1] Therefore, even if it works for a long time in a high-temperature environment, there will be no structural or performance changes.

- Corrosion Resistance

Graphite rotor vanes are highly corrosion-resistant and non-reactive to most acids, gases, and other corrosive chemicals that are commonly present in pumps’ working processes. It ensures the service life and reliability of rotor blades in various industrial environments.

- High Mechanical Strength

Graphite performs well in terms of resistance to bending and wear, allowing graphite vacuum pump vanes to withstand high-speed rotation for extended periods without being easily deformed or damaged.

- Good Chemical Stability

Graphite rotor vanes have good chemical stability and are not easily reactive with other chemicals. It enables rotor blades to operate stably in various environments while maintaining their structural and functional integrity.

- Excellent Self-Lubrication

Graphite materials have a good coefficient of friction, which can reduce friction with the pump housing, reducing wear and heat generation. This allows the graphite rotor vanes to rotate more smoothly, reducing the occurrence of faults.

Advantages of High-quality Graphite Rotor Vanes for Vacuum Pump

High-quality graphite rotor vanes made by reputed brands offer distinct benefits. Their advanced properties help vacuum pumps run more smoothly and efficiently over extended periods of heavy usage. Key advantages include:

- Improve the Stability of the Pump

The high-temperature resistance and corrosion resistance of graphite vanes ensures continuous usage in tough industrial environments without degradation. The robust structure and resistance to wear and tear allow the rotor blades to rotate stably and maintain their shape. This stability can avoid pump shutdown or damage caused by rotor blade failure, maintaining a stable vacuum environment.

- Improve Work Efficiency

Graphite’s unique layered structure and lubrication characteristics significantly lower the frictional coefficient of vacuum pump rotors. This enhances the mechanical efficiency of the pump. In addition, due to the good thermal conductivity of the graphite material, graphite rotor vanes can quickly transfer the heat generated by friction, reducing the impact of heat on the pump and improving the pump’s working efficiency.

- Extend the Service Life of the Pump

As graphite vanes are highly durable and can resist damage from heat, chemicals, and physical stresses, they can withstand cyclic usage for an extended duration. Moreover, less wear means lower replacement frequency, which helps reduce repair and replacement costs and indirectly extends the pump’s service life.

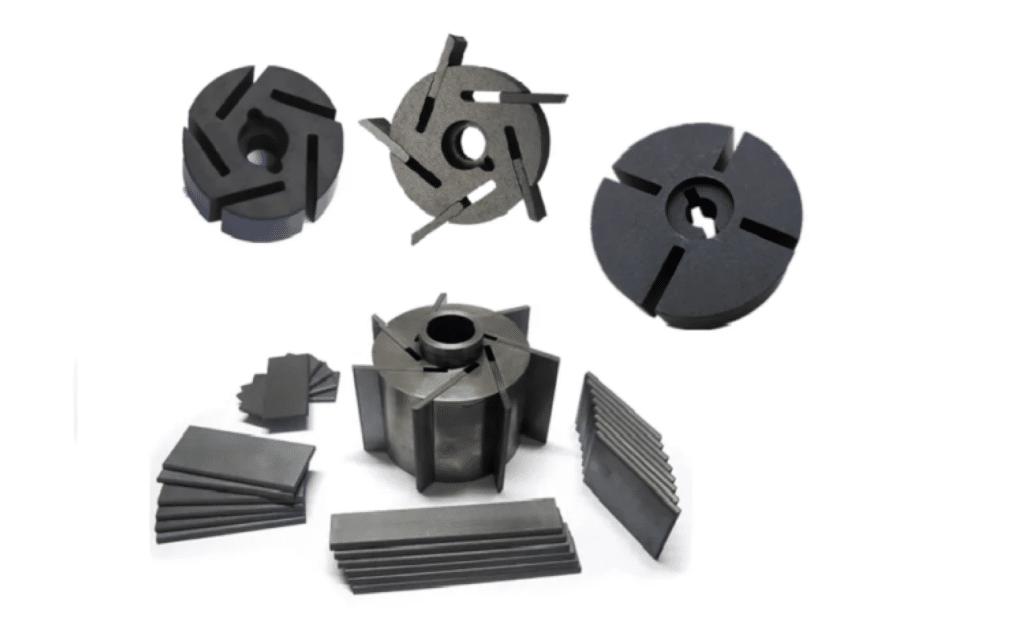

Improve Vacuum Pumps’ Performance with JUNTY’s Rotors and Vanes

JUNTY has been a leading manufacturer and supplier servicing the fluid and gas control industries for over two decades. Headquartered in Chicago, U.S., the company offers a vast portfolio of resistant products, including rotors, vanes, seals, and more for industrial vacuum applications.

JUNTY’s rotors and vanes leverage high-purity proprietary materials developed through extensive R&D. They are made from advanced graphite compounds, exhibiting higher strength, greater corrosion resistance, and optimized self-lubricating properties to enhance pump performance. Furthermore, the company’s in-house manufacturing allows full customization and quality oversight at each stage. Some key benefits of JUNTY’s rotors and vanes include:

- Improved mechanical efficiencies

- Heat dissipation ensures stable operation even at elevated temperatures

- Minimal wear throughout the service life of the vacuum pump

- Reduced friction for energy savings

- Material selection includes resin-bonded graphite, carbon graphite, and electrographite

Conclusion

Overall, using high-quality graphite rotor vanes can help improve vacuum pumps’ stability, efficiency, and lifespan. These advantages make rotor blades an indispensable key component in vacuum pumps and have been widely applied and promoted. When cooperating with quality brands like JUNTY, their high-quality products can help you maximize work efficiency. For more high-performance rotor and vane solutions, contact JUNTY today!

References

[1] Properties of Graphite. Available at: https://unacademy.com/content/nda/study-material/chemistry/properties-of-graphite/ (Accessed: 26 December 2023)