Every day technological advances are being made. One such development has been the inception of 3D printing, also called additive manufacturing. It might seem futuristic like VR, but is already in use in many industries, including the healthcare industry.

The basics of 3D printing

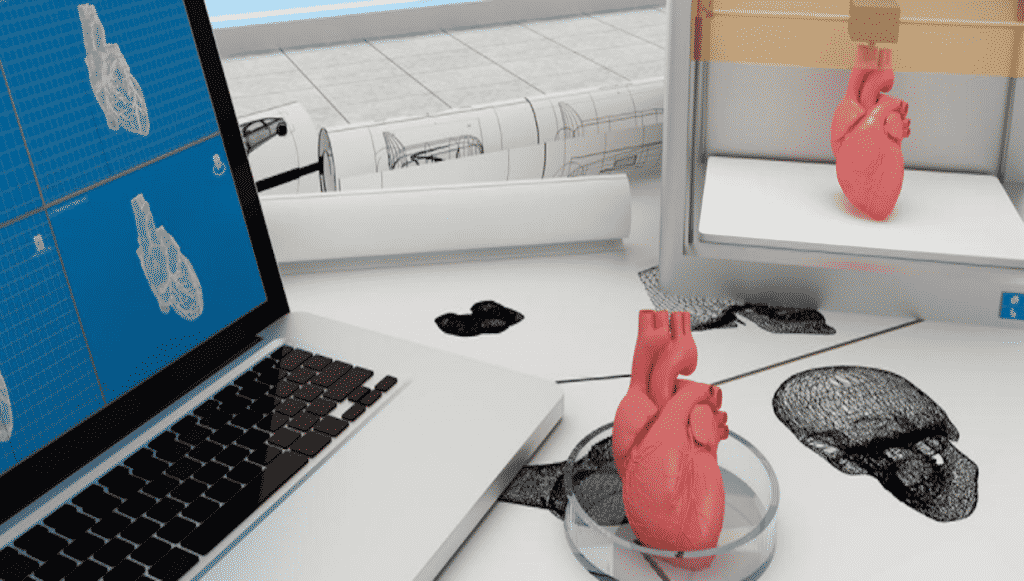

3D printing uses exactly the same principles of normal printing. Instead of printing one layer of ink onto paper or other material, the printer lays down multiple coats of a substance to build an object – almost any object. Both plastics and metals can be used in the manufacturing process, which can take between 4 to 18 hours. 3D printing can create a vast array of products, from furniture to prosthetics.

Application in medicine

There are hopes that the development and refinement of 3D printing will make the lives of doctors and patients easier, as well as saving money and time. A digital model of the desired object must be used in order to replicate it, but tweaks can be made to produce a one-of-a-kind article. This method has already been used to create prostheses, implants and medical tools.

It can be cheaper than and just as effective as tradition reconstructions and transplants and has been under development since the 1980s. For organs a slightly different approach is required, as the 3D printed object must be constructed by appropriate cells so that it can perform the same function as its real counterpart.

The cost

The value of the 3D printing has been growing steadily since its inception: predictions suggest that by 2025 it will be worth $3.5 billion by 2025, up from $713.3 million in 2016. There is concern among critics that the costs of 3D printers are prohibitively high, while advocates believe it saves time and money. Put into practice, 3D printing for an individual is exorbitant, but when it is applied in a massive industry such as the medical field, it cuts down costs in the long run.

Using 3D printers can speed up processes such as drug trials, as well as producing organs that could save lives and give hope to patients on waiting lists for transplants. Despite the fact that the undertaking is highly specialised, it can be much cheaper than transplanting an actual organ.

What about efficacy?

Printing organs, also termed “3D bioprinting”, is still developing, but in cases where it has been trialled, the accuracy and effectiveness has been worth the effort. When people need organ transplants, they usually have to wait for a suitable donor to be found, and even then, the transplanted organ may be rejected, sometimes resulting in the death of the patient. Using 3D bioprinting this problem can be circumvented by using the patient’s own cells to construct the necessary organ.

The process is still under development and is not widely used, but it is very probable that before long it will be refined and utilised to the benefit of both doctors and patients. In today’s world multiple people are added to transplant lists every day and while it’s easy to register right here for some things, it’s not so easy to do so for a transplant. Bioprinting could be the perfect solution.